PM Company Solution

Positioning itself as a “full life-cycle partner,” PM Company provided T Paper with a complete turnkey project service, from solution design and equipment supply to automation system integration and on-site installation and commissioning.

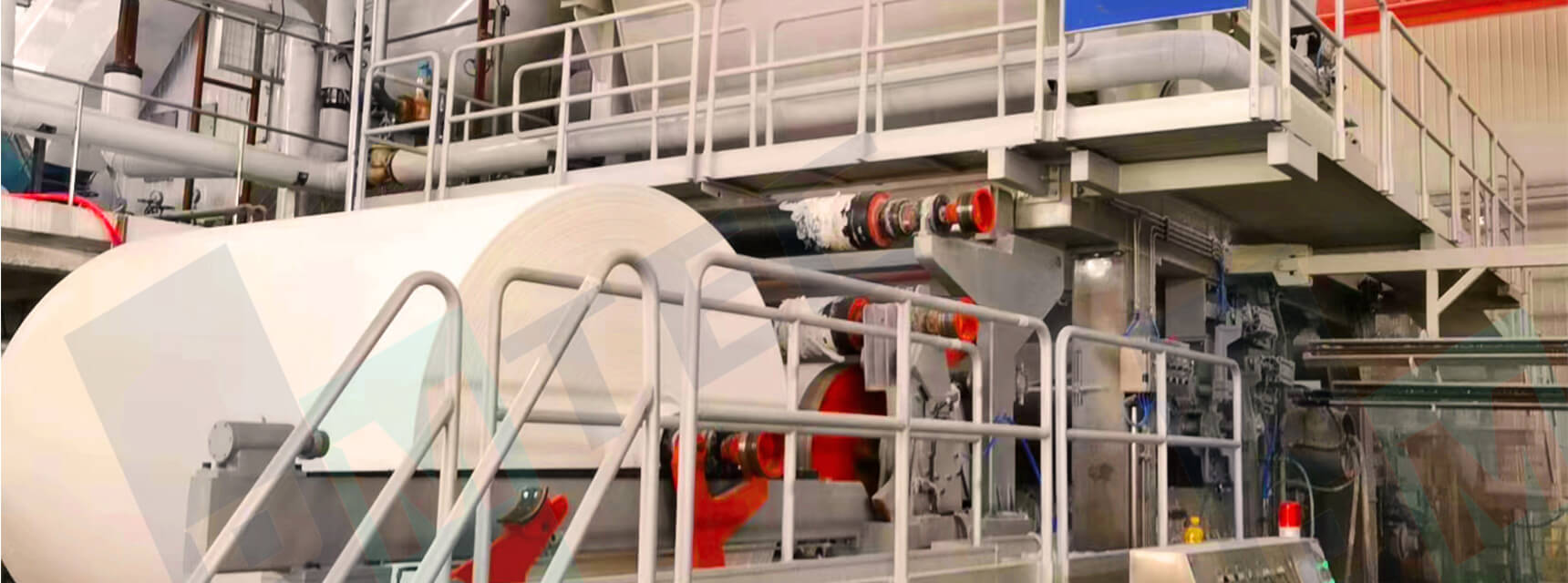

Core Equipment

The 3200mm width, 800m/min high-speed cultural paper machine independently developed by PM Company was adopted. This model applies several advanced hydrodynamic optimization designs to ensure the quality and production efficiency of the finished paper.

Automation System

- The PM MCS process control system is equipped to achieve precise and coordinated control of key processes such as pressing, drying, sizing, and reeling, effectively reducing production disturbances and ensuring the coordination and stability of paper machine operation.

- The PM QCS quality control system is introduced to perform online detection and closed-loop control of key quality parameters of the paper web, such as basis weight, moisture content, and thickness, to achieve refined management of paper quality. The basis weight variation is controlled within ±0.6%, which is significantly better than the industry average.

- A complete DCS distributed control system is constructed to achieve centralized monitoring and optimized management of all production stages in the plant, such as pulping, stock preparation, and water treatment, laying the foundation for the plant’s future intelligent production.

- The PM energy management system is integrated to perform real-time monitoring and optimization of energy consumption such as steam and electricity, achieving a comprehensive energy consumption of 0.88 tons of standard coal per ton of paper, which is more than 15% lower than the local average level, bringing significant operating cost savings to customers.

Project Management and Services

PM Company established an experienced project management team to strictly control project progress and quality. It completed all construction work from civil construction to successful paper production within 12 months, and provided comprehensive operation training and long-term after-sales technical support to ensure that customers can independently and efficiently operate the production line.

Implementation Results

- The project has a short construction cycle, and the first trial run was successful, fully demonstrating PM Company’s strong capabilities in paper machine design and manufacturing and project management.

- The paper quality is stable and reliable, and the basis weight variation is controlled within ±0.6%, significantly enhancing the product’s market competitiveness.

- Energy consumption is greatly reduced, and the comprehensive energy consumption per ton of paper is more than 15% lower than the local average level, bringing considerable economic and environmental benefits to customers.

- The comprehensive training and after-sales service provided by PM Company provide a solid guarantee for customers’ long-term stable production.

Customer Feedback

“PM Company’s technology and engineering execution are very professional. In particular, we received full support in training and after-sales service, which laid a solid foundation for our future development.”

—— General Manager of T Paper, Uzbekistan