NEWS

-

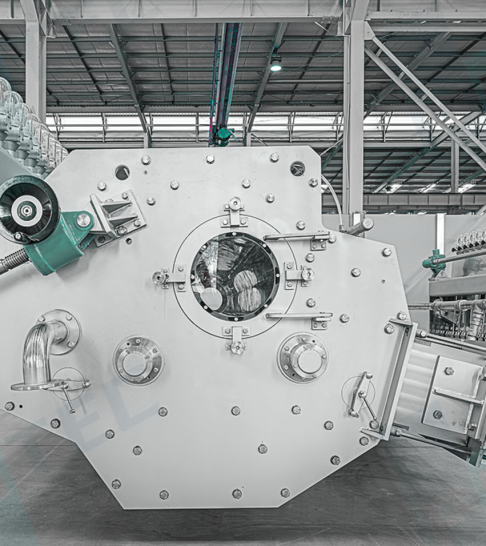

PM Technologies: Live Update on 300,000-ton Corrugated Boxboard Turnkey Project in HubeiLearn More

PM Technologies: Live Update on 300,000-ton Corrugated Boxboard Turnkey Project in HubeiLearn MoreThis undertaking showcases PM Technologies’ technical execution capabilities and end-to-end service excellence in large-scale paper projects.

HOT

All News

The latest blogs

-

Precision Ash Control: Engineering Global Process StabilityLearn More

Precision Ash Control: Engineering Global Process StabilityLearn MoreIt acts as a silent regulator that directly dictates the physical and chemical limits of your production line—affecting everything from fiber bonding to wastewater treatment performance.

-

OCC Refining Optimization: Strength Development vs. Machine RunnabilityLearn More

OCC Refining Optimization: Strength Development vs. Machine RunnabilityLearn MoreRefining performance is increasingly determined by fiber condition and system coordination, rather than refining energy input alone.

-

Practical Engineering Observations on Wire Blinding and TrackingLearn More

Practical Engineering Observations on Wire Blinding and TrackingLearn MoreAcross multiple forming section evaluations conducted by PMTEC, wire blinding and tracking deviation repeatedly appear as two typical, experience-driven issues. They are not complicated, but they clearly reveal how well the forming section is understood.

-

A Comprehensive Guide to Integrated Foam Control in Papermaking SystemsLearn More

A Comprehensive Guide to Integrated Foam Control in Papermaking SystemsLearn MoreFor production and process engineers, the key questions are not why foam exists, but where it originates, why it becomes uncontrollable, and how it can be managed in a sustainable, engineering-driven manner.

-

Engineering Synergy: A Strategic Report on High-Speed Paper Machine StabilityLearn More

Engineering Synergy: A Strategic Report on High-Speed Paper Machine StabilityLearn MoreAchieving high Overall Equipment Effectiveness (OEE) requires more than mechanical speed; it requires a seamless integration of process logic, automated intelligence, and mechanical precision.

-

From Design to Operation: Understanding Headbox Performance in PapermakingLearn More

From Design to Operation: Understanding Headbox Performance in PapermakingLearn MoreThe headbox is one of the most critical components of a paper machine. Its primary function is to deliver a uniform, stable, and well-dispersed fiber suspension onto the forming section, directly determining sheet formation quality, basis weight profile, and overall paper performance.