From System Diagnosis to Engineering Solutions

In modern pulp and paper production, foam is not merely a visible operational nuisance. More importantly, it is a direct reflection of system behavior.

For production and process engineers, the key questions are not why foam exists, but where it originates, why it becomes uncontrollable, and how it can be managed in a sustainable, engineering-driven manner.

Based on extensive experience across multiple paper grades and raw material structures, PMTEC has reorganized foam-related challenges from an engineering perspective, shifting the focus from listing causes to delivering practical, system-level solutions.

1. Where Foam Commonly Appears in Papermaking Systems

In industrial papermaking, foam does not occur randomly. Its appearance is strongly correlated with system layout, operating conditions, and circulation design. Identifying foam-prone locations is the first and most critical step in effective control.

| System Area | Typical Foam Behavior | Direct Operational Impact | Key Focus Areas |

| Pulping & Stock Preparation | Stable surface foam, false tank levels | Flow and consistency fluctuations | Resin load, agitation, elevation drops |

| White Water System | Foam overflow, air entrainment | Level instability, vacuum disturbance | System closure, DCS load |

| Wet End / Forming Section | Entrained air, foam spots | Pinholes, unstable drainage | Approach flow design |

| Coating System | Foaming in coating kitchens | Craters, surface defects | Shear conditions, formulation |

Foam is primarily a location-specific issue. Without clearly identifying where foam is generated and accumulated, corrective actions tend to be ineffective or purely symptomatic.

Key Engineering Drivers of Foam Formation

From an engineering standpoint, foam formation is rarely caused by a single factor. It is typically the result of several conditions acting simultaneously. Understanding these drivers allows mills to focus on controllable variables rather than symptoms.

Three Essential Conditions for Foam Formation

- Presence of air sources (entrainment, suction, negative pressure)

- Accumulation of surface-active substances

- Operating environments that stabilize bubbles

Main Foam Drivers – Engineering Overview

| Driver Category | Typical Sources | Mechanism of Impact |

| Raw Materials | Resin acids, fatty acid soaps, recycled fiber residues | Supply natural surfactants |

| Wet-End Chemistry | AKD/ASA hydrolysis products, additive interactions | Alter surface tension and charge balance |

| Process Conditions | High elevation drops, pumping shear | Introduce and disperse air |

| System Design | Closed white water loops, DCS build-up | Increase foam stability |

Foam problems are not inherently complex. The challenge lies in recognizing which conditions are being amplified and addressing them at the system level.

Hidden Consequences of Uncontrolled Foam

Foam-related issues are often underestimated because they rarely cause immediate shutdowns. However, their impact accumulates gradually across quality, efficiency, and cost dimensions.

Chain Reactions Caused by Foam Instability

| Impact Area | Typical Manifestations | Long-Term Consequences |

| Product Quality | Pinholes, foam marks, poor formation | Customer complaints, grade downgrades |

| Operations | Pump cavitation, poor drainage, speed limitations | Reduced runnability |

| Cost | Loss of fiber and chemicals | Increased cost per ton |

| EHS | Spills, corrosion, slippery floors | Safety and compliance risks |

When foam issues are ignored, they gradually evolve from operational inconvenience into measurable system losses.

PMTEC Integrated Foam Control Framework

Effective foam control must follow engineering priorities rather than rely on chemical intervention alone. PMTEC’s project experience consistently shows that system-oriented solutions outperform reactive treatments.

4.1 System and Process Solutions (Highest Priority)

- Optimize stock flow paths to minimize unnecessary elevation drops

- Improve system sealing to eliminate air ingress points

- Introduce structural foam-breaking or buffering zones in critical tanks

- Balance white water reuse to avoid excessive system closure

4.2 Physical Foam Control Measures

- Mechanical foam breakers and rotating defoaming devices

- Hydraulic spraying and surface agitation systems

- Centrifugal degassing and deaeration equipment

4.3 Chemical Foam Control as a Management Tool

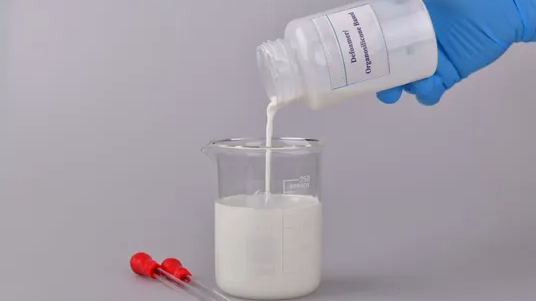

| Defoamer Type | Typical Application | Management Considerations |

| Silicone-based | Persistent, localized foam | Evaluate impact on sizing |

| Polyether-based | High-temperature, high-shear systems | Focus on stability |

| Mineral oil-based | Conventional systems | Control dosage and addition point |

Defoamers are not primary problem solvers; they are supportive tools once system conditions are stabilized.

From Reactive Defoaming to Preventive Control

Long-term operational stability depends on preventive management rather than corrective action. Foam control follows the same principle.

Key Management Practices

- Correlate foam occurrence with operating conditions and locations

- Periodically evaluate DCS levels in white water systems

- Use foam behavior as an indicator of wet-end chemical stability

- Avoid masking systemic issues through prolonged high defoamer dosage

When foam is managed as part of routine system control, defoaming shifts from emergency response to proactive optimization.

Conclusion

In papermaking systems, foam is not an isolated defect but a visible signal of overall system performance.

By integrating process optimization, physical control measures, and targeted chemical management, mills can simultaneously improve operational stability, product quality, and cost efficiency.

PMTEC remains committed to delivering engineering-based, sustainable solutions for the global papermaking industry.