Introduction

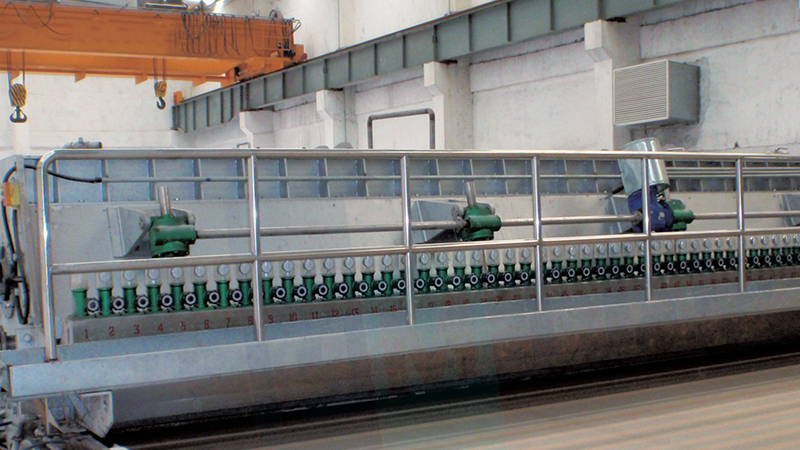

The headbox is one of the most critical components of a paper machine. Its primary function is to deliver a uniform, stable, and well-dispersed fiber suspension onto the forming section, directly determining sheet formation quality, basis weight profile, and overall paper performance.

With decades of project experience in stock preparation systems, approach flow systems, and forming section engineering, PMTEC has accumulated extensive know-how in headbox selection, system integration, and on-site optimization. This article combines industry-standard headbox theory with PMTEC’s practical engineering experience, providing a professional and application-oriented technical overview for paper mills.

Ⅰ、Technical Overview of Headboxes

1.1 Historical Evolution

The headbox has evolved alongside the paper machine for more than 200 years. From early gravity-fed open headboxes to modern high-turbulence hydraulic designs, technological progress has consistently focused on improving stock distribution uniformity, fiber dispersion, and controllability—key factors for higher machine speeds and improved paper quality.

Based on long-term project execution, PMTEC has observed that headbox evolution is closely linked to three driving factors: machine speed increase, higher formation requirements, and system-level stability demands.

1.2 Representative Headbox Types and Characteristics

To provide a clear engineering-oriented comparison, the following table summarizes commonly used headbox types, their main characteristics, and typical applications.

| Headbox Type | Main Characteristics | Typical Speed Range | Range Typical Applications | Engineering Focus (PMTEC View) |

| Open Headbox | Static head level control, simple structure | <200 m/min | Low-speed machines, rebuild projects | Flow distribution and space constraints |

| Air-Cushioned Headbox | Jet velocity controlled by air pressure | 300–700 m/min | Medium-speed cultural & packaging papers | Stable air pressure and profile control |

| Hydraulic Headbox | High-intensity micro-scale turbulence | 1000 m/min | High-speed and wide paper machines | System-level integration with approach flow |

| Multi-Layer Headbox | Multiple stock layers formed simultaneously | Project-specific | Packaging and specialty papers | Layer structure and furnish optimization |

| High-Consistency Headbox | Reduced white water volume and energy use | Medium–high speed | Energy-saving projects | Overall system coordination |

In PMTEC’s engineering practice, headbox selection is always evaluated together with the entire stock preparation and approach flow system to ensure long-term operational stability.

From a system engineering perspective, PMTEC emphasizes that successful application of high-consistency forming depends on coordinated design of stock preparation, approach flow, and white water recovery systems.

Ⅱ、Functions and Performance Requirements of Headboxes

2.1 Core Functions

A modern headbox must be capable of fulfilling the following core functions:

| Function Category | Technical Description | Impact on Paper Quality |

| Uniform Stock Delivery | Stable jet across full machine width | Uniform basis weight profile |

| Fiber Dispersion | Suppression of fiber flocculation | Improved formation and strength |

| Jet Control | Precise control of jet speed and angle | Fiber orientation and retention |

| Structural Stability | Slice geometry unaffected by pressure and temperature | Long-term profile stability |

| Maintainability | Easy inspection and cleaning | Reduced operational risk |

PMTEC’s engineering philosophy focuses on system stability and controllability, rather than isolated equipment performance.

2.2 Key Performance Requirements

- Uniform basis weight distribution without machine-direction streaks

- Stable cross-machine profiles under varying operating conditions

- No stock buildup or deposition inside the headbox

- Easy cleaning and maintenance access

- Accurate and adjustable jet-to-wire (J/W) speed ratio

Ⅲ、 Headbox Structure and Functional Design

3.1 Main Structural Components

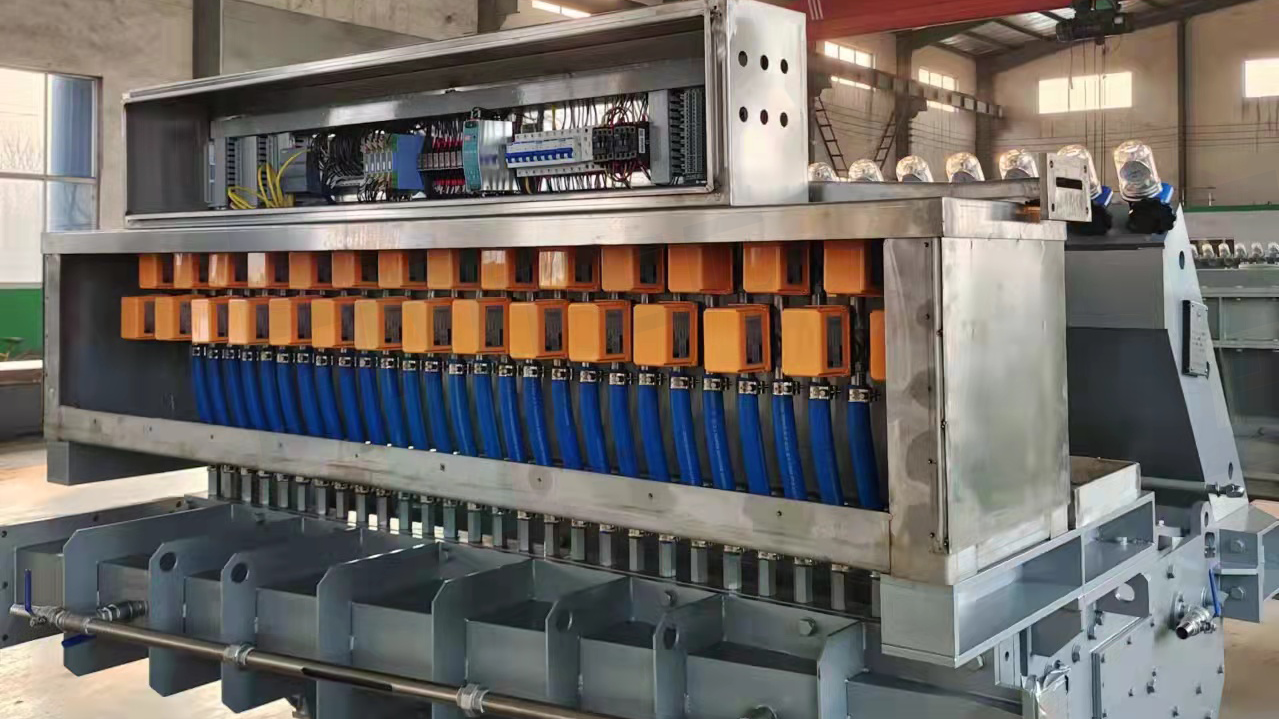

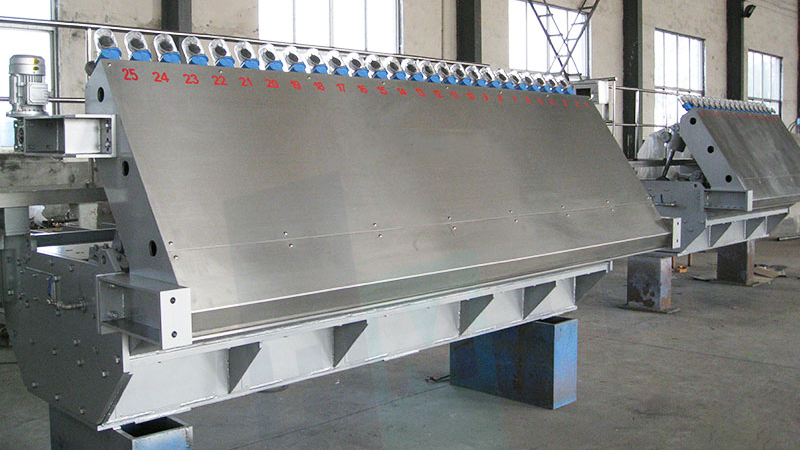

A typical headbox consists of three functional sections:

- Stock distribution system (manifold)

- Flow straightening and turbulence generation section

- Jet delivery and slice section

3.2 Functional Description

Stock Distribution System

Designed according to fluid dynamics principles, the manifold ensures uniform pressure and flow distribution across the machine width. In PMTEC projects, special attention is paid to manifold geometry to minimize cross-machine deviations.

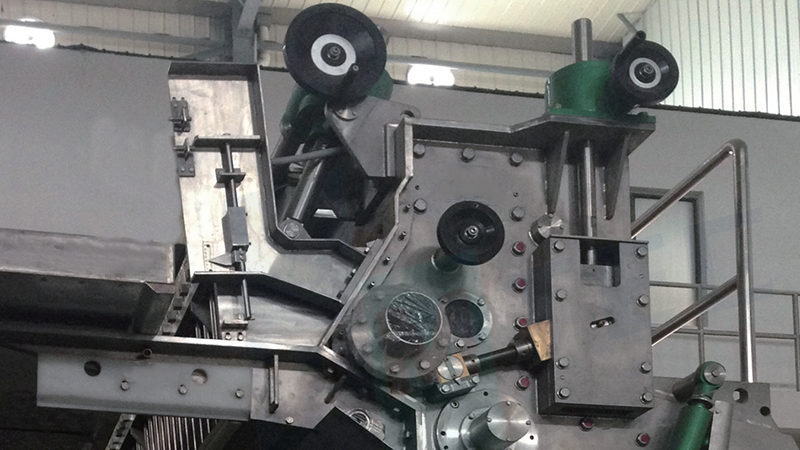

Flow Straightening and Turbulence Generation

Turbulence generators disperse fibers effectively and suppress floc formation. PMTEC engineers select turbulence intensity based on furnish characteristics, refining degree, and target paper properties.

Jet Delivery System

The slice section controls jet angle, velocity, and thickness. PMTEC emphasizes precise mechanical rigidity and adjustment accuracy to ensure long-term profile stability.

Ⅳ、Practical Application in Paper Mill Operations

4.1 Headbox Selection Criteria

Based on PMTEC project experience, headbox selection typically follows the engineering logic below:

| Selection Factor | Key Consideration | Engineering Recommendation |

| Machine Speed | Jet stability requirement | Hydraulic headbox for high-speed machines |

| Paper Grade | Formation and layer structure demands | Hydraulic or multi-layer headbox |

| Raw Materials | Fiber length and filler content | Determines turbulence design |

| Energy Saving | White water volume and power consumption | High-consistency forming with system support |

| Future Expansion | Capacity upgrade margin | Reserve adjustment capability |

PMTEC evaluates these factors comprehensively to ensure stable operation and long-term performance.

4.2 Operation and Maintenance

PMTEC supports customers with commissioning guidance, parameter optimization, and operator training, focusing on:

- Stable pressure and consistency control

- Cleanliness management to prevent deposition

- Early diagnosis of formation-related issues

Ⅴ、System Integration and PMTEC Engineering Value

From PMTEC’s perspective, headbox performance must be evaluated at system level, not as a standalone component. Successful projects rely on coordinated design of:

- Stock preparation and approach flow systems

- White water circulation and recovery

- Forming and drying section capacity matching

By combining equipment supply, engineering design, and technical service, PMTEC helps paper mills achieve stable operation, consistent quality, and long-term reliability.

Conclusion

The headbox is a decisive element in papermaking, directly influencing formation quality, production stability, and resource efficiency. Through rational selection, precise operation, and system-level optimization, paper mills can significantly enhance product performance.

Leveraging extensive engineering experience and comprehensive service capability, PMTEC continues to support customers worldwide with practical, reliable, and sustainable headbox and approach flow solutions—always based on sound papermaking fundamentals rather than excessive promotion.