The vacuum system is the lifeline of the dewatering process in a modern paper machine, playing a decisive role in sheet dryness, press performance, and felt condition. Facing increasingly stringent environmental regulations and energy efficiency requirements, the paper industry is accelerating its transition from traditional high-energy-consumption technologies to efficient, environmentally friendly dynamic vacuum technology. The Turbine Vacuum Pump is the core of this green technological revolution, while Maglev (Magnetic Levitation) technology represents the next generation of ultra-efficient vacuum system development.

Ⅰ、Industrial Vacuum Pump Comparison: Technological Evolution and Optimization from Water Ring to Maglev

Equipment selection is the first step toward achieving energy-saving goals. The evolution of vacuum technology in the paper industry clearly demonstrates a path from low-speed, high-water- Positive Displacement to high-speed, water-free, ultra-efficient Dynamic systems.

PMTEC continuously monitors cutting-edge industry technologies and provides in-depth analysis and comparison of the characteristics of these three mainstream vacuum pumps.

| Vacuum Pump Type | Operating Principle | Core Characteristics |

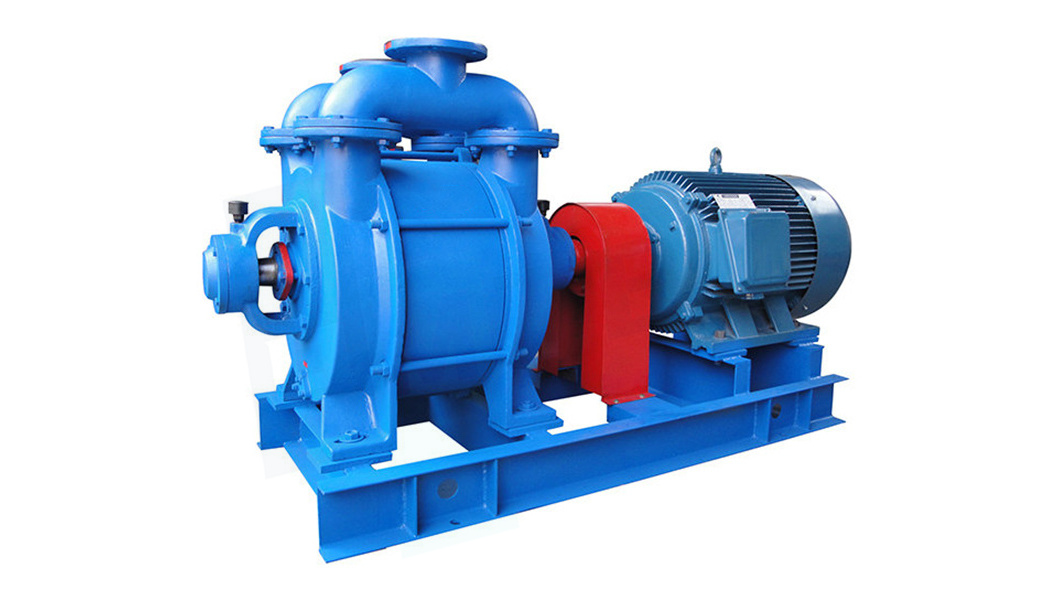

| Water Ring Vacuum Pump | Positive Displacement. Uses a liquid ring (typically water), created by an eccentric impeller, as the sealing and compression medium. | Traditional Workhorse. Robust structure, but high energy and water consumption (typically 2-3 times that of a turbo pump); good tolerance for media, but maintenance involves cooling water and circulation systems. |

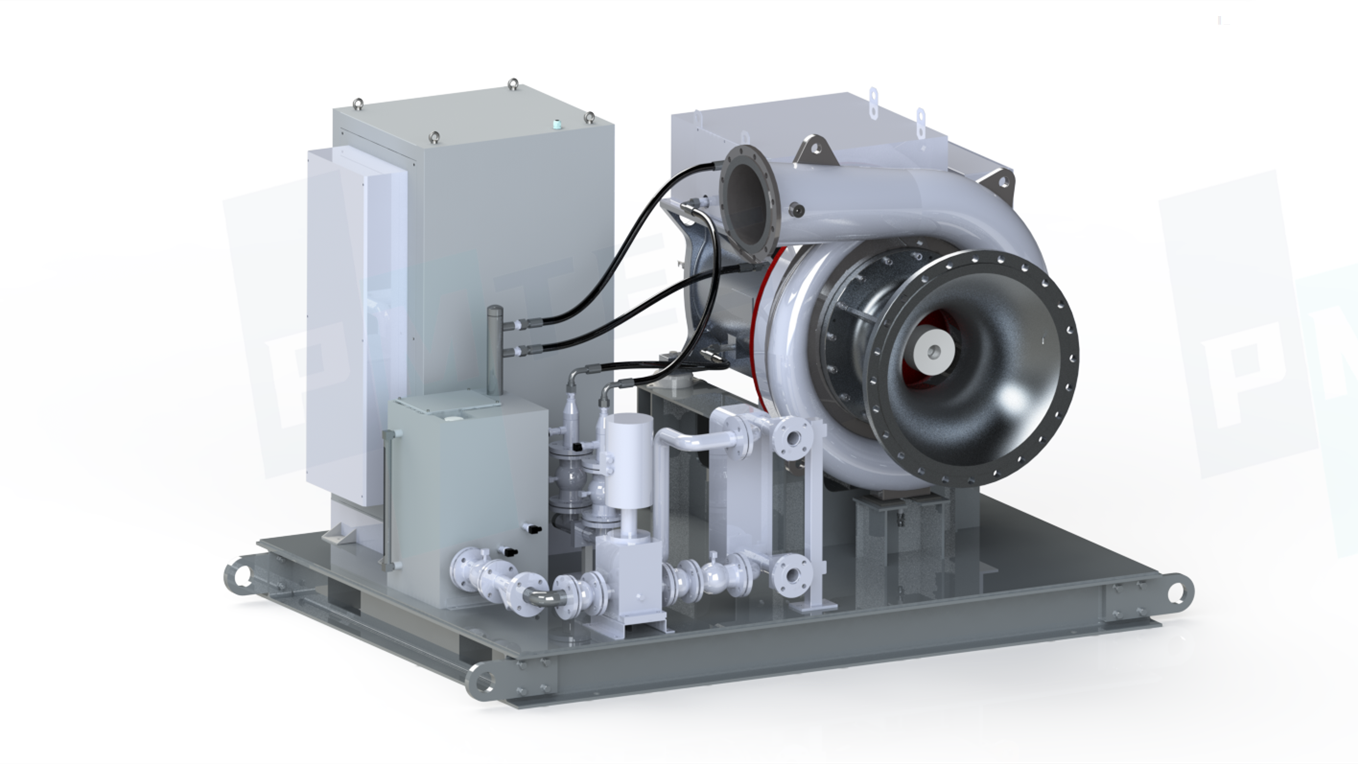

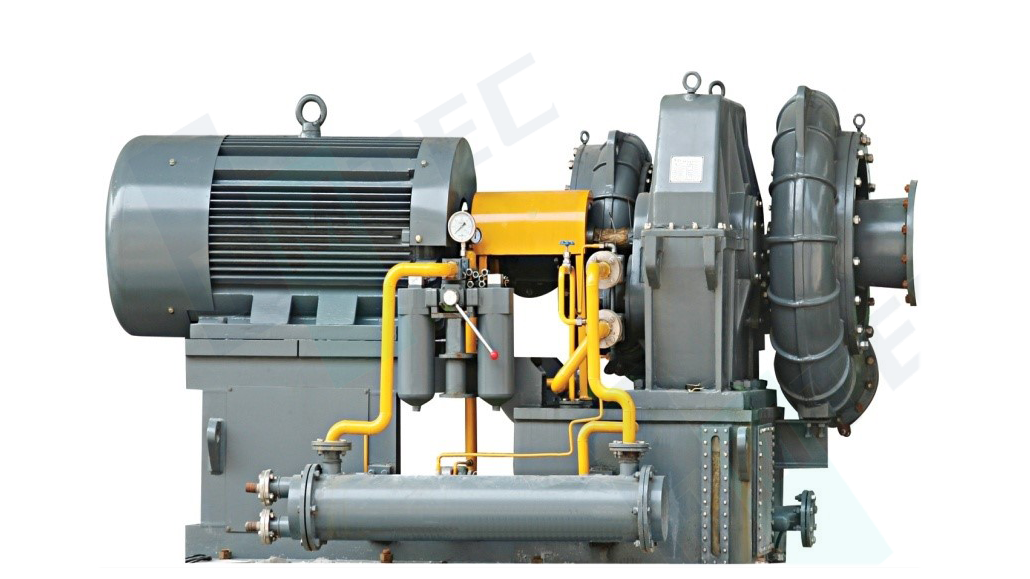

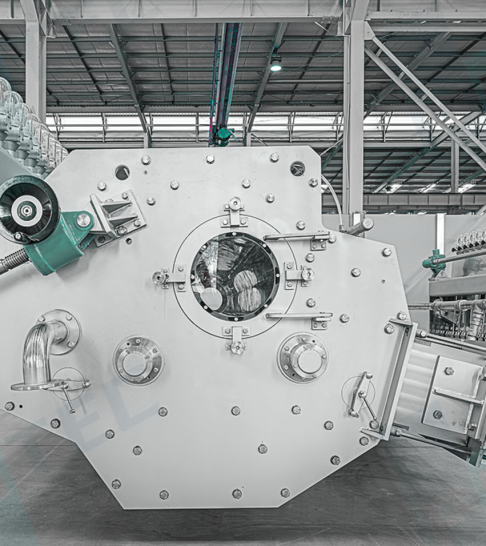

| Turbine Vacuum Pump | Dynamic. Uses a high-speed rotating radial impeller to accelerate and compress the gas to achieve vacuum extraction. | Current Mainstream, Excellent Energy Efficiency. Extremely high operating speed (tens of thousands of revolutions), zero sealing water consumption; extremely sensitive to vibration; lower initial investment than Maglev pumps. |

| Maglev Turbine Pump | Dynamic + Innovative Support. Uses a high-speed turbine impeller, and replaces traditional mechanical bearings with Maglev . | Future Direction, Ultra-High Precision. Eliminates mechanical friction, enabling higher speeds and lower energy consumption; virtually zero mechanical wear; highly complex control system, high initial investment cost. |

The Turbine Vacuum Pump has become the primary force for energy efficiency upgrades, achieving a complete optimization over the traditional Water Ring Vacuum Pump.

The Maglev Turbine Pump represents the limit of vacuum pump technology optimization; its characteristic of eliminating mechanical friction is a new direction that professional technical teams like PMTEC are continuously monitoring, signaling a future maintenance model shift from mechanical wear to electronic control and sensor diagnostics.

Ⅱ、Revolutionary Advantages and Value of Turbine Vacuum Pumps

The Turbine Vacuum Pump, through its advanced aerodynamic design and frequency conversion control technology, has completely revolutionized the paper industry’s perception of vacuum system energy consumption. It brings about not only a reduction in energy bills but also a comprehensive upgrade in production processes and environmental sustainability.

| Advantage Category | Technical Feature | Core Value |

| Ultimate Energy Efficiency | Utilizes highly efficient radial impeller design and VSD for precise control of constant pressure and variable flow. | Energy consumption can be reduced by 30% to 70% compared to water ring pumps, substantially cutting electricity and operating costs, leading to a short return on investment period. |

| Environmental Friendliness & Water Conservation | “Dry” design, with zero consumption of sealing or working water. | Completely eliminates water waste and simplifies water circulation systems; eliminates the need for cooling towers and chemical treatment associated with liquid ring pumps. |

| High-Grade Exhaust Heat Recovery | High-speed operation generates high-temperature exhaust air (100°C–180°C), with high thermal energy grade, easy for recovery. | Up to 75% of absorbed power can be recovered as heat for use in heating process water or supplementing dryer section heat, achieving overall energy balance optimization in the production process. |

| Flexible Process Control | VSD allows real-time, precise adjustment of vacuum levels. | Can dynamically adapt to changes in machine speed, paper grade, and felt condition, achieving precise optimization of vacuum requirements, and stably improving sheet dewatering and dryness. |

The Turbine Vacuum Pump shows clear advantages in energy conservation, emission reduction, water resource protection, and system flexibility. Its high efficiency is attributed to complex high-speed mechanical design and precise VSD control, but this also brings new maintenance challenges.

Ⅲ、Professional Challenges in Operating High-Speed Turbo Pumps

The efficient operation of turbo pumps depends on extremely high rotational speeds—tens of thousands of RPM—which impose strict requirements on precision and operating environment.

By combining expertise in rotating machinery diagnostics with deep knowledge of papermaking processes, PMTEC helps mills overcome these challenges and ensures long-term stability and efficiency of vacuum systems.

3.1 High-Speed Rotordynamics and Vibration Sensitivity

- Challenge:

High-speed rotors are highly sensitive to slight imbalance. Even minimal deposits, uneven corrosion, or blade wear can create destructive vibration at high speeds, posing risks to bearing life and operational safety.

- PMTEC Solution:

PMTEC applies advanced vibration spectrum analysis and phase diagnostics (including Bode/Nyquist analysis) to distinguish imbalance, misalignment, and stiffness issues. PMTEC also provides precise on-site dynamic balancing to restore rotor accuracy with minimal downtime.

3.2 Media Sensitivity and System Integrity.

- Challenge:

Turbine pumps are extremely sensitive to particles, water droplets, and entrained air. Foreign material may damage the impeller or cause vacuum fluctuations, reducing overall system efficiency.

- PMTEC Solution:

PMTEC integrates mechanical diagnostics with papermaking process expertise, helping clients optimize separators, improve air–water separation efficiency, calibrate vacuum control, and conduct full system audits to ensure long-term reliability.

3.3 Reliability Risks, Preventive Maintenance & Future Trend of Maglev Turbo Pumps.

- Challenge:

High-speed equipment failures are sudden and potentially severe, requiring predictive monitoring. At the same time, maglev turbine pumps shift maintenance from mechanical wear to electromagnetic control and sensor-based monitoring.

- PMTEC Solution:

PMTEC offers comprehensive preventive maintenance: vibration diagnosis, bearing monitoring, lubrication management, and performance evaluation. PMTEC is also prepared for maglev pump applications by monitoring rotor levitation status, harmonic analysis, and control-system stability—helping customers transition to next-generation high-efficiency vacuum technology.

Managing a turbo vacuum pump requires expertise in rotordynamics, vibration analysis, media handling, and system engineering.

With long-standing practical experience, PMTEC delivers reliable technical support while continuing to invest in emerging technologies such as maglev pumps—helping mills maintain high-efficiency vacuum systems both today and in the future.

Ⅳ、Epilogue: PMTEC and Strategic Partnership in the Paper Industry

The Turbine Vacuum Pump is a strategic asset for the paper industry in achieving green and efficient production. Their stable operation directly determines the enterprise’s energy consumption level and market competitiveness. Furthermore, attention to cutting-edge technologies like the Maglev Turbine Pump determines an enterprise’s future development potential.

PMTEC, as a professional technical service provider rooted in the paper industry, offers value that extends far beyond singular repair services.

Our core mission is to help paper companies establish the most reliable and efficient vacuum system operation and maintenance structure by integrating accurate vibration diagnosis, efficient on-site dynamic balancing technology, and continuous mastery of next-generation technology trends like magnetic levitation.

PMTEC’s technical capabilities cover everything from optimizing traditional water ring pumps and precisely repairing current turbo pumps, to condition monitoring of future maglev systems.

We serve as your strategic partner in technological upgrades and maintenance strategies, aiming to help you maximize the energy-saving potential of your turbo vacuum system, ensure the long-term stable operation of critical assets, and facilitate the paper industry’s comprehensive and sustainable green leap.