At PMTEC, we provide high-performance wet-end solutions developed through the integration of European Finnish technology and collaborative R&D with leading papermaking research institutes.Our starch-based biopolymer series is engineered to optimize machine performance and enhance fiber strength across diverse papermaking processes.

PM-1: Cationic Starch-Based Biopolymer

Cationic Solution for Enhanced Strength and Retention

PM-1 is a cationic starch-based wet end strength agent designed to improve paper strength, retention, and paper machine performance under low cationic demand conditions.

Key Functions and Benefits:

Dry Strength Enhancement: Applied as a dry strength agent for both paper and paperboard.

Resource Efficiency: Increases ash content without loss of paper strength, effectively lowering pulp consumption.

System Purification: Reduces anionic trash in the wet-end system.

Operational Boost: Improves drainage, retention performance, and overall paper machine operating efficiency.

Surface Quality: Improves linting and dusting to enhance final printability.

Performance Advantages:

Obstacle Reduction: Lowers the level of system obstacles affecting machine operation.

Contaminant Control: Effectively lowers pitch and sticky contaminants.

System Stability: Minimal impact on system charge, allowing efficient operation in low cationic demand environments.

Compatibility: Fully compatible with retention aids, drainage aids, and microparticle systems.

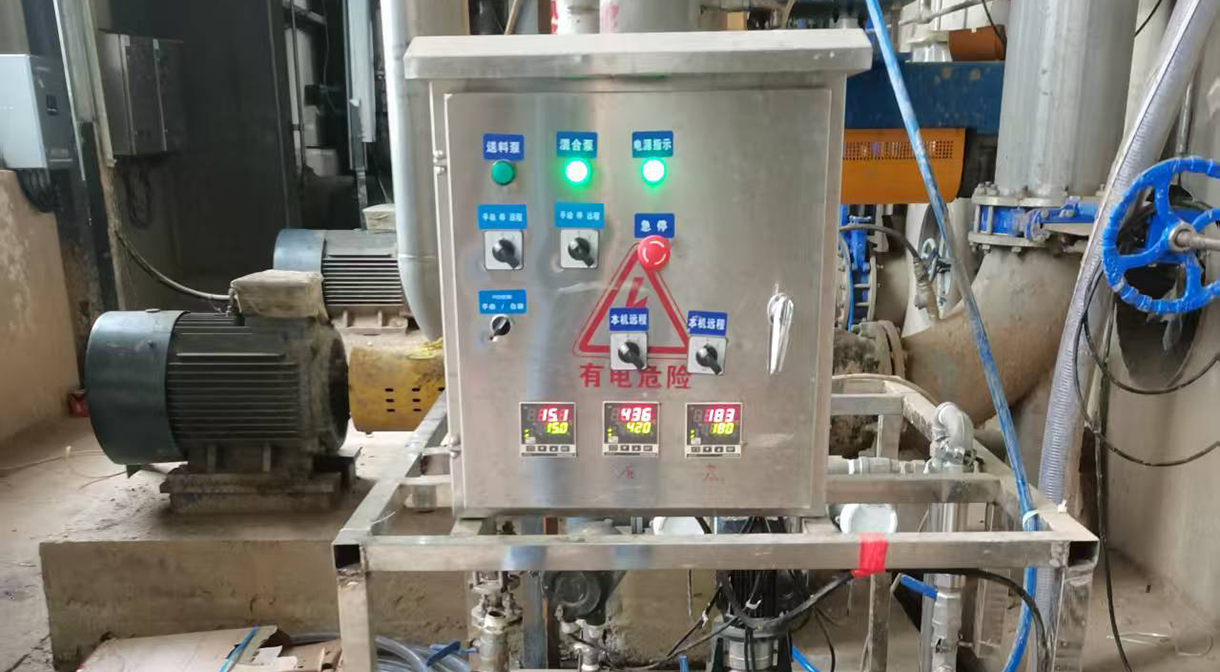

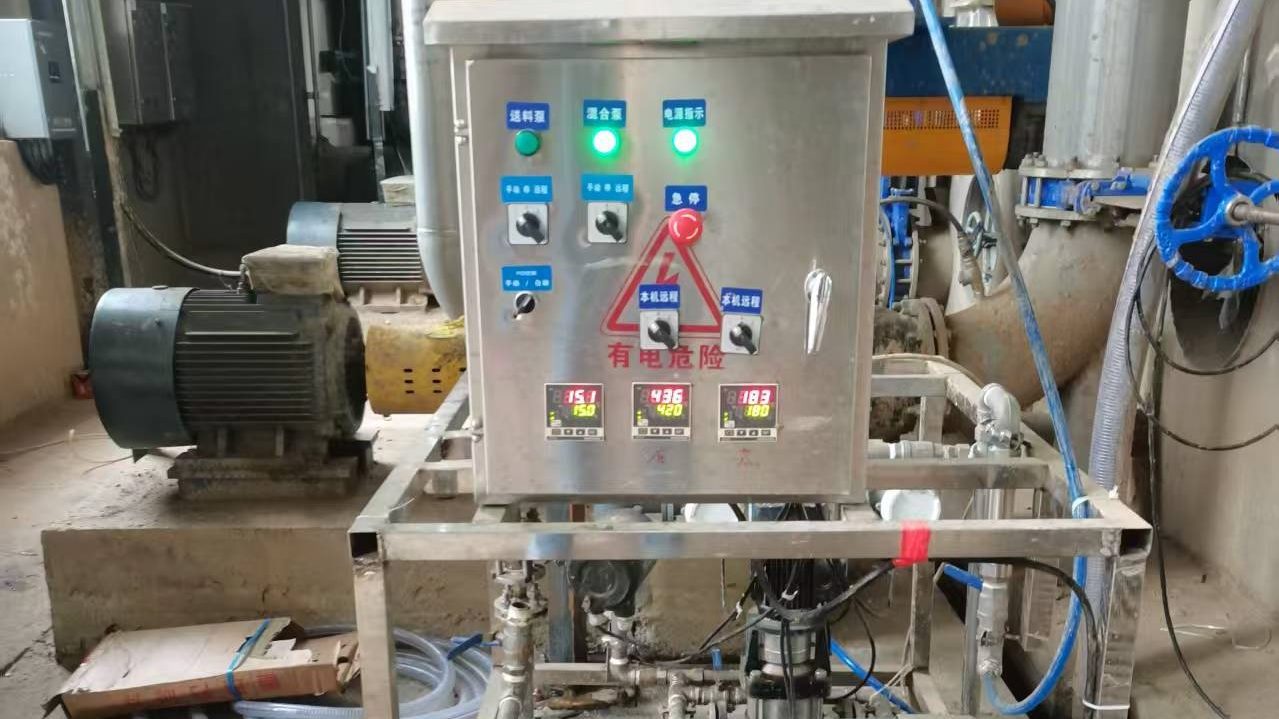

User-Friendly: Features an easy application with a simple dosing operation.

Technical Data

| Item | Specification |

| Chemical Structure | Branched starch-based biopolymer |

| Appearance | Viscous light brown transparent liquid |

| Active content | 15 ± 1% |

| Ionicity | Cationic |

| Viscosity (23°C) | < 5000 mPa·s |

| pH | 9 – 11 |

PM-2: Amphoteric(slightly anionic) Starch-Based Biopolymer

Advanced Solution for Wet-End Stability and Charge Control

PM-2 is an amphoteric(slightly anionic) starch-based wet end strength agent designed to enhance paper strength while assisting in critical wet-end system charge control.

Key Functions and Benefits:

Dual-Action Strength: Enhances paper strength through specialized wet-end addition.

Charge Management: Assists in controlling wet-end system charge to prevent excessive cationic conditions.

Synergy: Enhances the effectiveness of other cationic chemicals and improves dry/wet strength.

Efficiency: Improves retention, drainage, and overall machine efficiency.

Print Quality: Reduces linting and dusting for improved printing results.

Performance Characteristics:

High Efficiency: Enhances retention while reducing overall chemical consumption.

System Stabilization: Specifically stabilizes wet-end system performance.

Operation: Improves overall paper machine efficiency with easy application using simple dosing equipment.

Technical Data

| Item | Specification |

| Chemical Structure | Branched starch-based biopolymer |

| Appearance | Viscous brown liquid |

| Active content | 20 ± 1% |

| Ionicity | Amphoteric, slightly anionic |

| Viscosity (23°C) | 500 – 2000 mPa·s |

| pH | 4 – 6 |

Application & Compliance

Application Instructions

To ensure optimal performance, follow these standardized dosing guidelines:

- Pre-dilution: Recommended dilution with 20 times water before addition.

- Typical Dosage: 1 – 2 kg per ton of paper.

- Addition Points:

| Strength-focused: | Thick stock. |

| Retention/Drainage-focused: | Fan pump inlet. |

Safety and Regulatory Compliance

Both PM-1 and PM-2 meet international safety standards for food contact materials:

- FDA: 21 CFR 176.170 and 176.180.

- BfR: XXXVI and XXXVI/2 (PM-1); XXXVI (PM-2).

- GB Standard: PM-2 complies with GB 9685-2016.

Logistics & Handling

- Packaging: 1-ton IBC or customized options.

- Storage: Maintain at 10 – 30°C; avoid freezing.

- Handling: Lower temperatures may increase viscosity; dosing and handling equipment should consider this condition.

- Environment: Follow local environmental regulations. Leaked liquid can be absorbed with inert materials.

- Safety: Industrial use only. Follow general chemical labor protection; no special protection for toxic chemicals is required. Refer to MSDS for detailed safety information.

- Shelf Life: ≥ 12 months for PM-1; ≥ 9 months for PM-2.

Technical Service

PMTEC provides professional technical support to assist with product selection and application optimization tailored to your specific paper machine and paper grade requirements.