Auxiliary Equipment

Core business areas

The Invisible Engine of Paper Mill Efficiency – Comprehensive Support for Water, Power, and Steam Savings

Auxiliary systems are the backbone of continuous and stable operations in stock preparation and paper machines, encompassing key equipment such as pulp pumps, vacuum pumps, steam and condensate systems, online fabric cleaning, air compressors, fans, and finished product handling and packaging. As a vital part of PM Company, we leverage extensive experience from China’s large-scale paper mills to provide global customers with efficient, energy-saving, and reliable auxiliary solutions. These systems ensure uninterrupted operation of main equipment while significantly reducing water, power, and steam consumption, helping paper mills optimize overall operational costs.

Core Auxiliary Equipment

Full-Coverage Solutions to Meet Production Needs

Pulp Pumps and Water Pumps

High-Efficiency Pulp Pumps

Flow range: 10-2000m³/h

Material: Duplex wear-resistant stainless steel (2-3x longer lifespan)

Energy-saving design: 15%-20% lower energy consumption than traditional pumps

Industrial Water Pumps

Flow range: 5-1000m³/h

Material: High-chrome iron/stainless steel (corrosion and wear-resistant)

Vacuum Systems

Liquid Ring Vacuum Pumps

Vacuum level: -0.09~-0.098MPa

Energy-saving optimization: 25% lower energy consumption than traditional models

Turbo Vacuum Pumps

High-speed operation (≤3000rpm)

Low-maintenance design (maintenance interval ≥8000 hours)

Crescent former

Cost-efficient solution for tissue (12-40g/m²)

Steam and Condensate Systems

Efficient Condensate Recovery

Recovery rate ≥90%

Energy savings: Reduces steam consumption by 0.1-0.2 tons/ton paper

Flash Tanks and Steam Traps

Automatic drainage (reduces steam waste)

Pressure-adaptive design (adapts to various operating conditions)

Online Fabric Cleaning Systems

High-Pressure Cleaning Units

Cleaning pressure: 50-150bar (adjustable)

Water-saving design: 40% less water usage than traditional cleaning methods

Control Systems

Real-time fabric cleanliness monitoring

Automatic adjustment of cleaning frequency and pressure

Air Compressors and Fans

High-Efficiency Air Compressors

Capacity: 1-100m³/min

Energy-saving mode: Reduces standby power consumption by 50%

Centrifugal Fans

Airflow range: 1000-50000m³/h

Low-noise design (≤75dB)

Finished Product Handling and Packaging

Finished Product Handling and Packaging

Automated Conveying Systems

Conveying speed: 10-60m/min (adjustable)

Intelligent sorting (accuracy ≥99.5%)

High-Speed Packaging Machines

Packaging efficiency: ≥20 rolls/hour

Automatic labeling and palletizing

Core Value Proposition

Energy Savings

Stable Operations

Cost Optimization

Water Savings

White water recycling and fabric cleaning systems reduce water usage by ≥40%

Power Savings

Efficient designs lower overall power consumption by 15%-20%

Steam Savings

Condensate recovery systems reduce steam consumption by 0.1-0.2 tons/ton paper

Continuous Operations

Low-maintenance designs ensure trouble-free operation

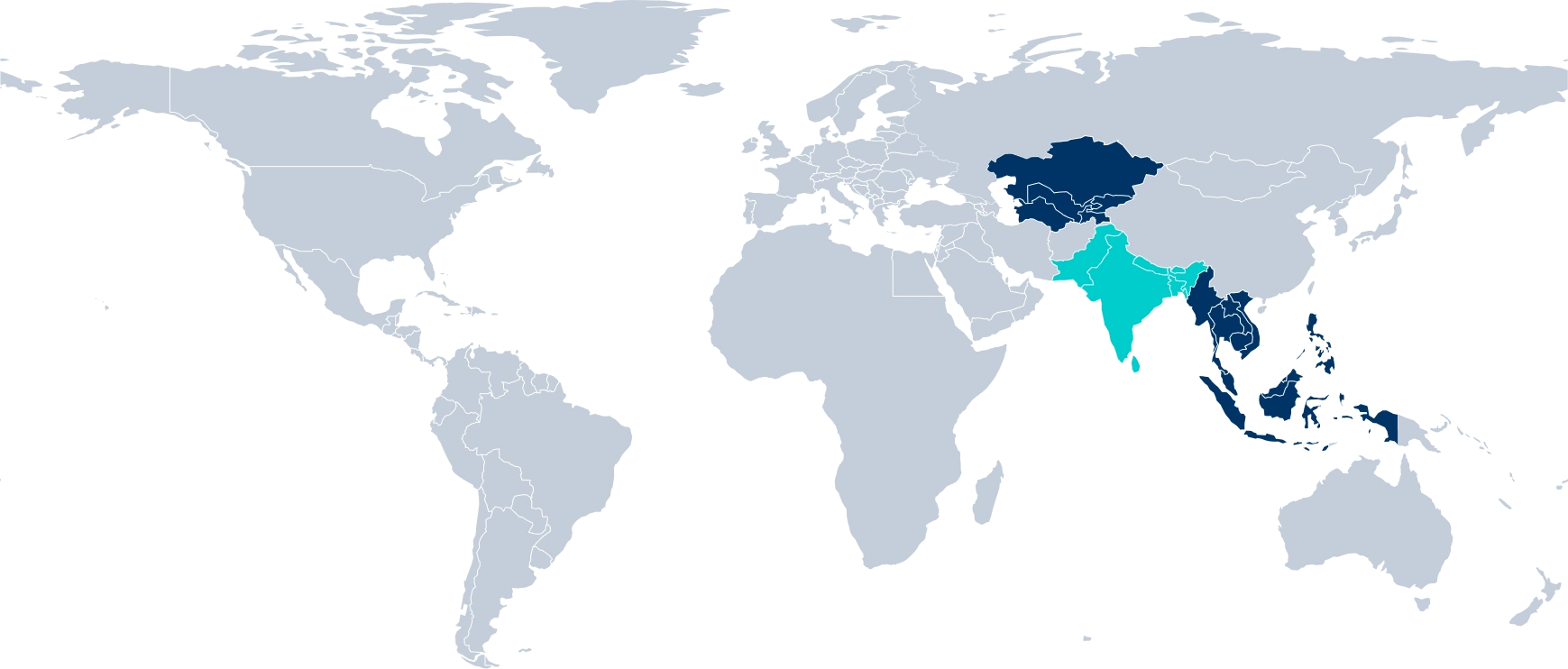

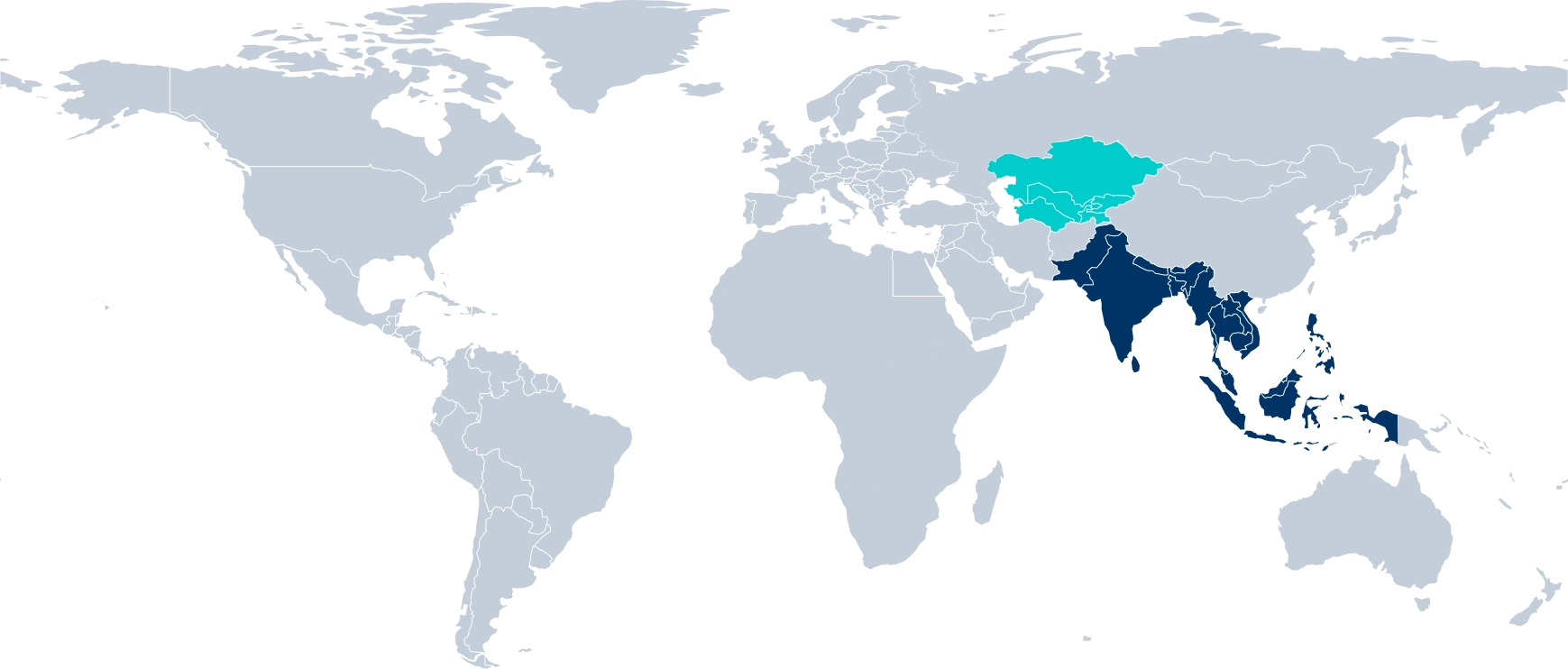

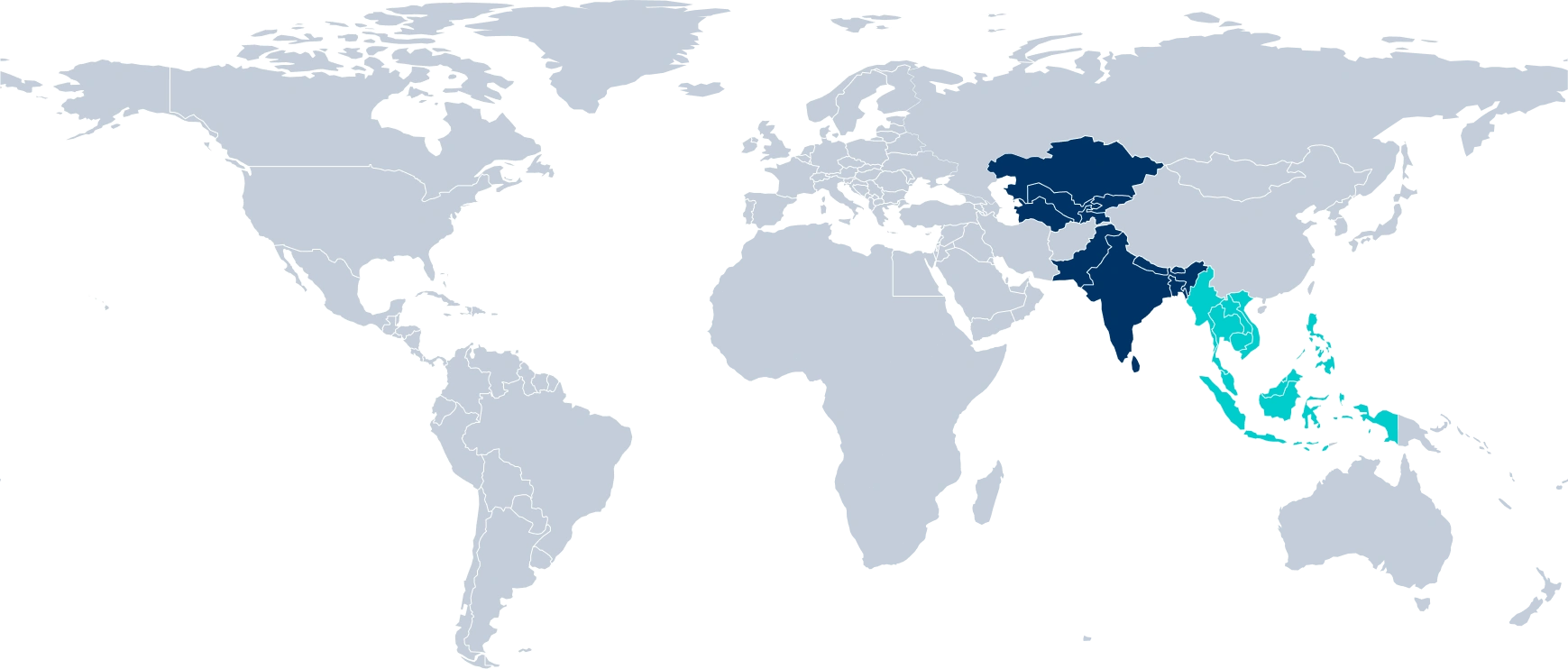

Global Project Highlights

One-Stop Services

End-to-End Support from Design to Operations

Custom Design

Tailored auxiliary configurations based on mill size and process needs

Rapid Delivery

Pre-assembled core equipment (reduces installation time by 30%)

Remote Support

Real-time monitoring and early warning systems (minimizes unplanned downtime)

OUR PRODUCTS

Provide high-quality products

-

High-Speed Rewinder Selection Guide

with energy consumption simulation

-

PDF Title01

with energy consumption simulation

-

PDF Title02

with energy consumption simulation