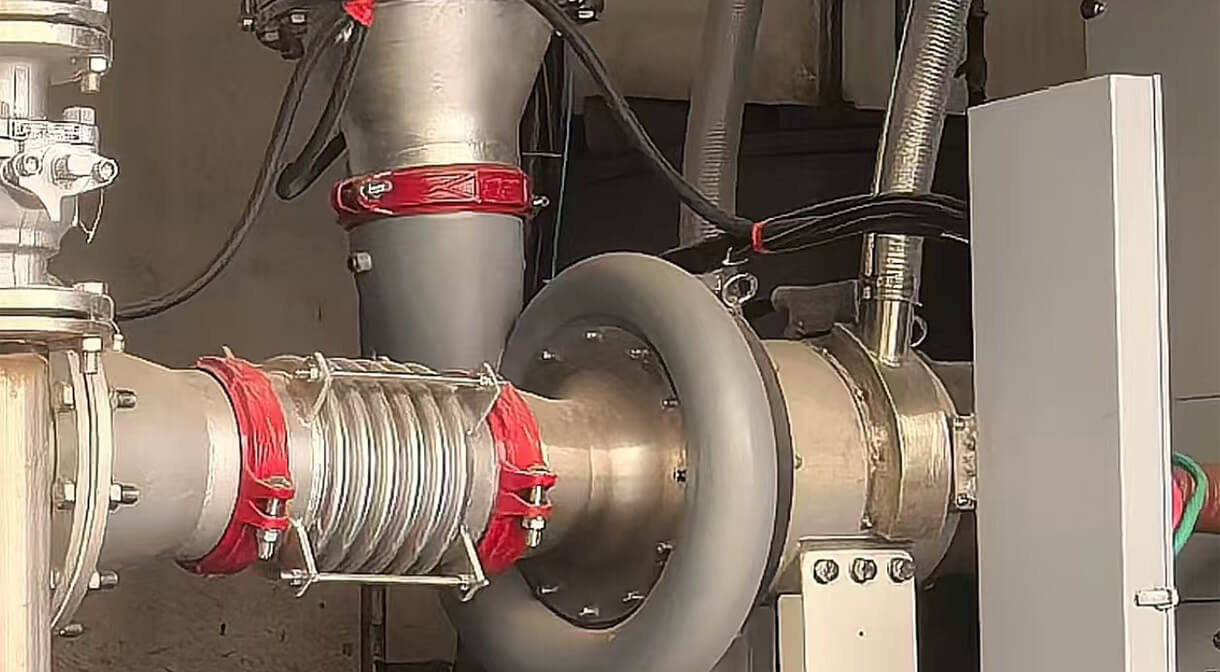

Core Equipment Configuration

Innovation and Application of Oil-Free Vacuum Technology

Magnetic Bearing System

Friction-free operation

Electromagnetic field dynamically controls rotor suspension (gap 0.2-0.5mm), no lubricating oil required, avoiding the wear and maintenance of traditional bearings.

Extra-long life

Laboratory-verified continuous operation > 20,000 hours, 10 times longer than ball bearing life (data source: GB/T 30253-2013).

Three-Dimensional Flow Impeller Technology

Aviation-grade precision manufacturing

Five-axis CNC machined aluminum alloy impeller, single-stage pressure ratio up to 2.3, suitable for vacuum degree -10kPa to -70kPa.

Fluid efficiency>92%

CFD optimizes flow channel design to reduce turbulence losses and ensure high vacuum stability (±1.5% fluctuation).

Permanent Magnet Synchronous Direct Drive Motor

Energy efficiency level 1

Motor efficiency 96%±1%, direct drive structure eliminates gearbox loss, variable frequency speed regulation accuracy ±0.5%.

Low-noise operation

Fully enclosed design combined with magnetic suspension vibration reduction, noise ≤80dB(A), meeting ISO 4871 industrial environment standards.

Industrial verification-Hubei paper mill energy efficiency increased by 51.8%

Project Background

Project Background: A paper company in Hubei with an annual output of 300,000 tons originally used a 146kW water ring vacuum pump unit, which faced problems such as high power consumption (18.5kW·h per ton of paper), vacuum fluctuation (±8%), and annual maintenance costs exceeding RMB 80,000.

Transformation plan and data

- Equipment replacement: Deploy TRV200 series magnetic levitation vacuum pumps to match the papermaking dehydration process requirements.

- Third-party test results (2023 HVAC-SZ-2307 test report):

- Operating power: 70.3kW (51.8% lower than the original equipment)

- Power consumption per ton of paper: 9.6kW·h (annual power saving 1,320,000kW·h)

- Vacuum stability: Fluctuation range ±1.2%, improving paper dehydration uniformity.

- Maintenance cost: <¥5,000 per year, no need for lubrication and mechanical parts replacement.

Customer Feedback

“The magnetic levitation pump not only reduces electricity costs, but also reduces downtime for maintenance. The vacuum control is more precise, which directly helps improve product quality.”

—— Equipment Director of a Paper Company in Hubei

Industry adaptability

Oil-Free Solutions from Papermaking to Multiple Fields

- Papermaking process: Fourdrinier dewatering box, press roll vacuum control, white water recovery system.

- Customized Design:

- Anti-corrosion coating: To cope with the acidic medium of waste pulp (pH 3-5).

- High temperature module: withstands 120℃ steam condensation environment and is suitable for thermal systems.

- Cross-industry applications: chemical process vacuum, food and medicine pollution-free transportation, power condensation system.

Service and Support

Global Technical Collaboration Network

Localized technical team

A network of engineers covering North America, Europe, and Southeast Asia, providing on-site surveys and solution designs.

Spare parts supply system

6 major storage centers around the world, 48-hour emergency response for key parts.

Remote diagnostic support

Provide fault prediction and optimization suggestions based on operation data log analysis.

Why do global companies choose us?

- Authoritative certification: China Energy Efficiency Star (2020-2021), GB/T 19001 quality management system.

- R&D Strength: National Enterprise Technology Center, leading the drafting of industry standards for magnetic levitation equipment.

- Sustainable Commitment: A single unit reduces carbon emissions by 180 tons per year (taking a 200kW unit as an example).