Process-Driven Pump Selection

Optimized for Specific Operational Demands

Coarse Screening Stage

- Challenge: String-like plastic rope impurities prone to tangling

- Solution: Open Impeller Pumps

- Design: Non-clogging open impeller (passes solids up to 50mm)

- Material: Duplex stainless steel (SAF 2205)

- Flow Range: 50-800m³/h

- Features: Effectively prevents string-like plastic rope impurities from tangling, ensuring non-clogging operation

De-sanding Stage

- Challenge: High content of impurities, significant abrasion

- Solution: Abrasion-Resistant Material Pumps

- Design: Closed impeller pumps suitable for high-abrasion environments

- Material: High-chrome cast iron (HRC 58-62) or ceramic-coated shafts

- Pressure: 0.3-0.8MPa

- Features: High hardness materials (up to HRC 65), extending service life and reducing maintenance frequency

Fan Pump (Approach Flow System)

- Challenge: Low pulse for stable pulp quality

- Solution: Low-Pulse Centrifugal Pumps

- Pulse Rate: ≤±1.5% (vs. 5% in standard pumps)

- Design: Double-suction impeller with volute diffuser

- Material: 316L stainless steel for chlorine resistance

- Features: Provides stable pulsation rates, ensuring consistency in the headbox and pulp quality

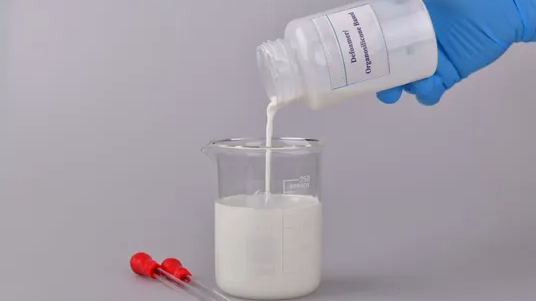

Chemical Additives

- Challenge: Different chemicals require specific materials and shear protection

- Solution: Adaptable Screw Pumps and Other Pump Types

- Design: Select appropriate pump types based on chemical properties (e.g., magnetic drive pumps, PTFE-lined pumps)

- Material: PTFE lining or other corrosion-resistant materials

- Features: Zero leakage design, shear protection, suitable for various chemical additives

Technical Advantages

Material Science + Hydraulic Precision + Process Expertise

Abrasion Resistance

- Hardness up to HRC 65 for sand-laden stock

- Ceramic-coated shafts with a lifespan exceeding 20,000 hours

Corrosion Management

- Material selection matrix based on pH/chemical exposure

- ISO 12944 C5-M coating for tropical mills

Energy Savings

- IE3/IE4 motors with VFD control (15%-30% power savings)

- Hydraulic efficiency up to 82% (ISO 5198 standard)

PM Selection Guide

Match Your Process with Confidence

| Process Stage | Pump Type | Key Features | Material Grade |

| Coarse Screening | Open Impeller | 50mm solid passage | SAF 2205 |

| De-sanding | Closed Impeller | High abrasion resistance | Cr30 High-Chrome |

| Fan Pump | Double-Suction | ≤1.5% pulse | 316L/Alloy 20 |

| Chemical Additives | Screw Pump | Zero leakage | PTFE-lined |