Boiler & ETP

Core business areas

Chinese Engineering Expertise Empowers Global Paper Industry – Integrated Boiler & Wastewater Solutions for Pulp & Paper Plant EPC Projects

PM Company unites a veteran engineering team with 20+ years of experience in pulp and paper plant construction. Our experts have led 30+ large-scale paper mill EPC projects, delivering end-to-end solutions that seamlessly integrate boiler systems, wastewater treatment, and paper production processes. As a specialized technical service provider, we focus on precision equipment selection and process-driven design to ensure optimal alignment with your plant’s operational needs.

Boiler Systems: Energy Solutions Engineered for Paper Production

EPC-Level Integration for Steam Cost Optimization

Multi-Fuel Adaptive Technology

Biomass Boilers

- ≥88% thermal efficiency (supports wood pulp, recycled fiber, and hybrid production lines)

- Ash recycling modules (reduce solid waste costs by 15-25%)

Coal-Fired Boilers

- Steam pressure precision control (tailored for drying sections and chemical preparation)

- Flue gas heat recovery (preheats white water, cutting energy use by 12-15%)

Gas/Oil Boilers

- <20-minute load response (synchronizes with paper machine start-stop cycles)

EPC Advantage

- Steam-Process Energy Modeling (integrates pulping, forming, coating, and drying energy demands)

- Full-system design from fuel storage to emission control (eliminates equipment silos)

Effluent Treatment Systems: Closed-Loop Water Management

Process-Synchronized Design for Sustainable Operations

Anaerobic Treatment UnitBiomass Boilers

- COD removal rate ≥85% (optimized for high-strength pulping wastewater)

- Biogas yield: 0.35m³/kg COD (directly feeds boiler systems or onsite power generation)

Aerobic Treatment Unit

- Aeration energy consumption <0.8 kWh/ton (AI-driven load adjustment aligned with production schedules)

- White water reuse rate ≥90% (achieves zero freshwater intake in forming sections)

EPC Engineering Value

- Digital water balance twin system (real-time monitoring of pulping, forming, and cooling water flows)

- Fiber recovery integration (reduce fiber loss by >15%)

Core Differentiators

EPC-Level Integration

Process-Driven Design

Lifecycle Optimization

Beyond Equipment Supply

- Boiler selection based on paper machine drying curves and steam demand profiles

- Wastewater capacity pre-designed for pulp type flexibility (e.g., virgin vs. recycled fiber)

Risk Mitigation

- Redundant critical equipment design (ensures 24/7 production continuity)

- BIM-powered clash detection (prevent 95% of construction conflicts)

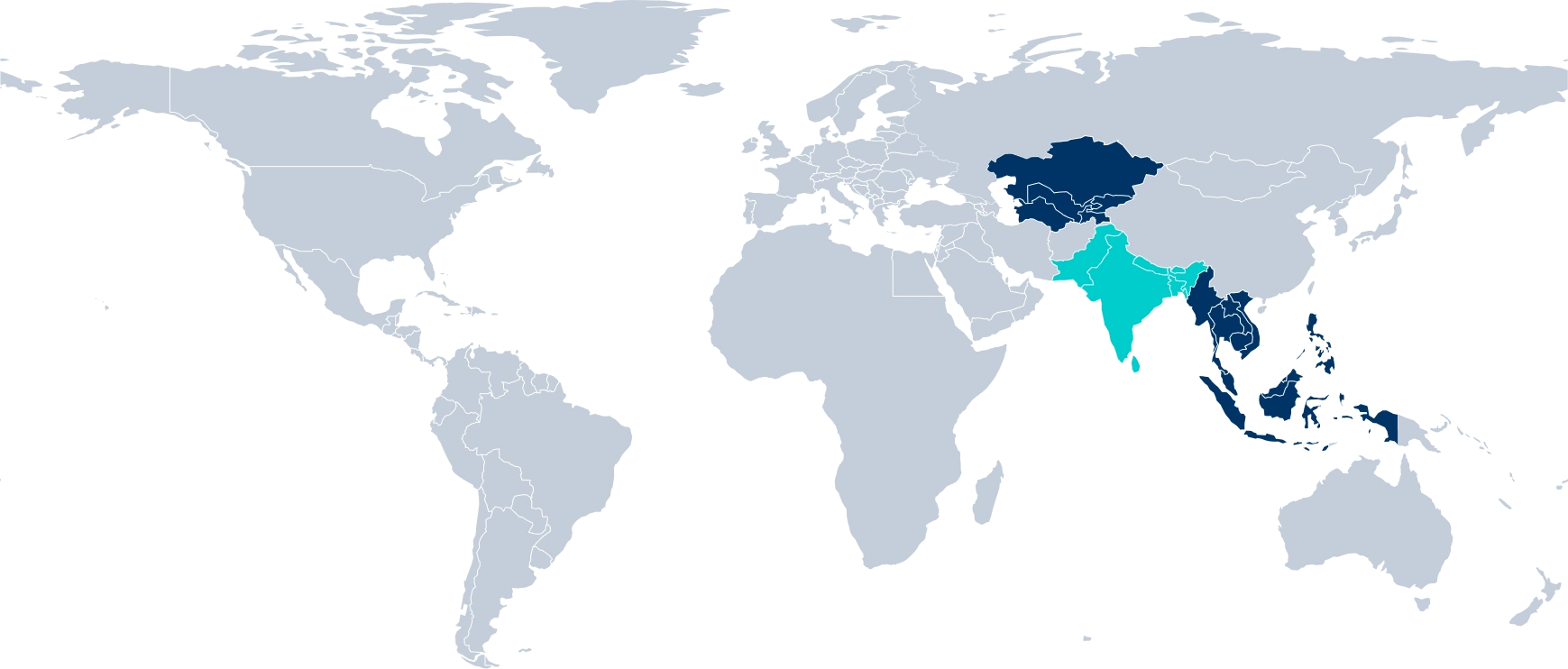

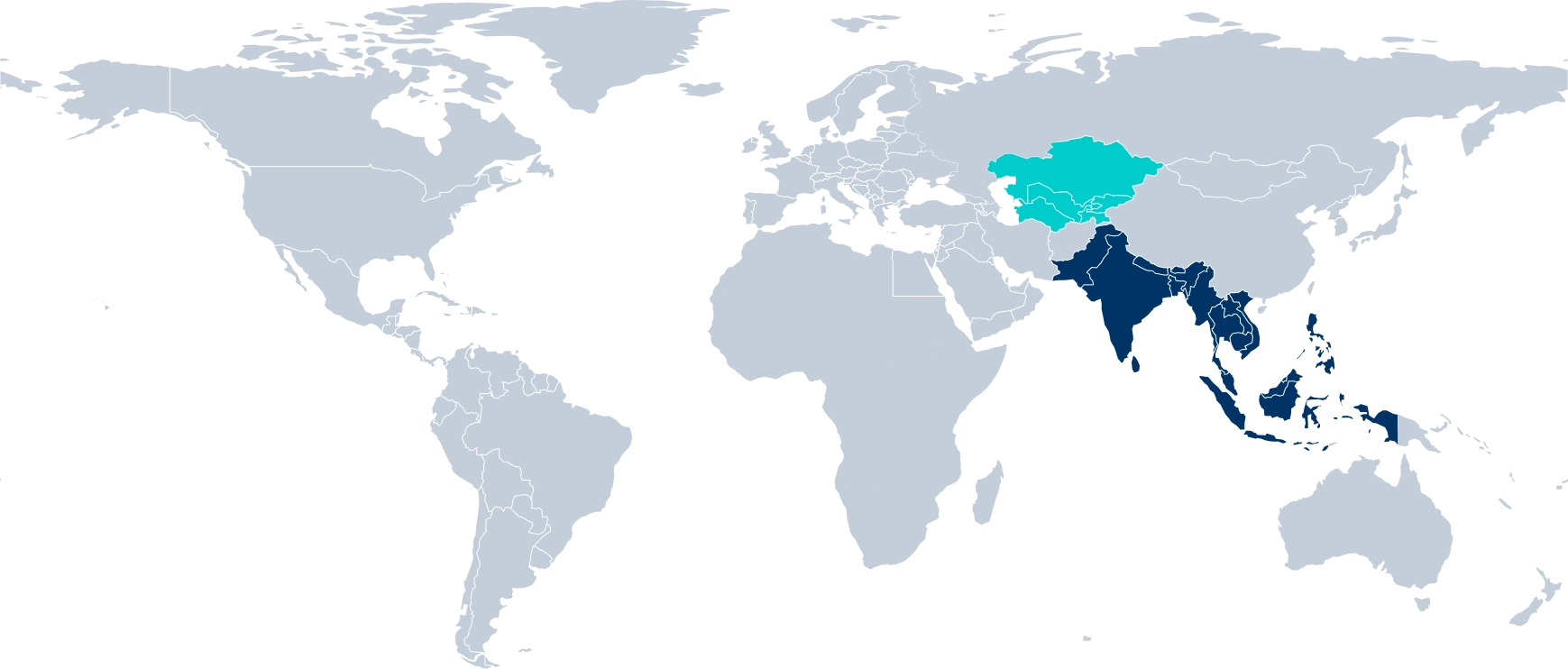

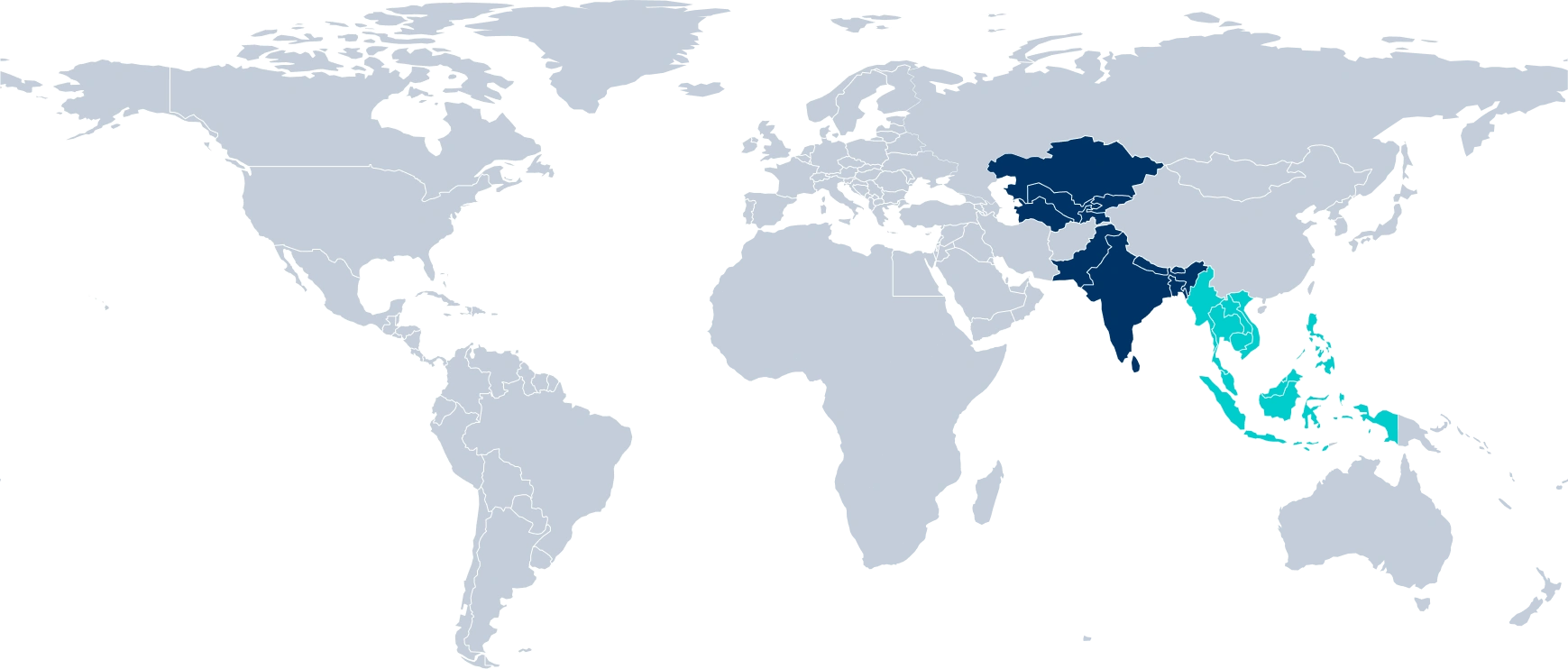

Global Project Highlights

Technical Service Portfolio

Seamless Support from Blueprint to Operation

Energy & Water Audit

- Steam network thermal loss 3D scanning

- Water value-stream analysis (identify 20%+ cost-saving potential)

EPC Engineering Delivery

- Process-embedded boiler and wastewater system design

- ISO-compliant interface management for cross-system integration

Smart Operation Support

- Boiler combustion auto-optimization controls

- Wastewater AI Early Warning platform (predicts parameter deviations 4+ hours in advance)

OUR PRODUCTS

Provide high-quality products

-

High-Speed Rewinder Selection Guide

with energy consumption simulation

-

PDF Title01

with energy consumption simulation

-

PDF Title02

with energy consumption simulation