Paper Machines & Key Components

Core business areas

Global Full-Scope Solutions for Paper Production Excellence – Efficient Systems for Packaging, Tissue, and Specialty Papers

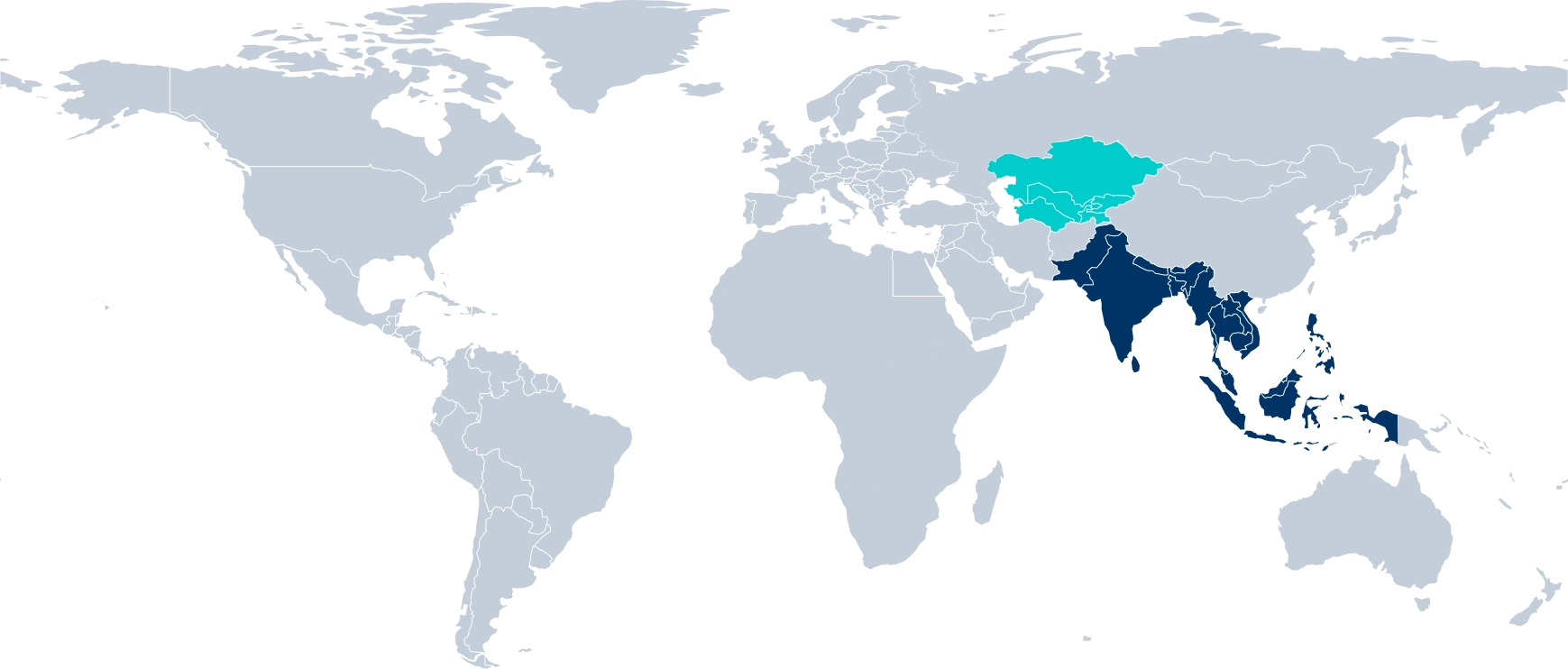

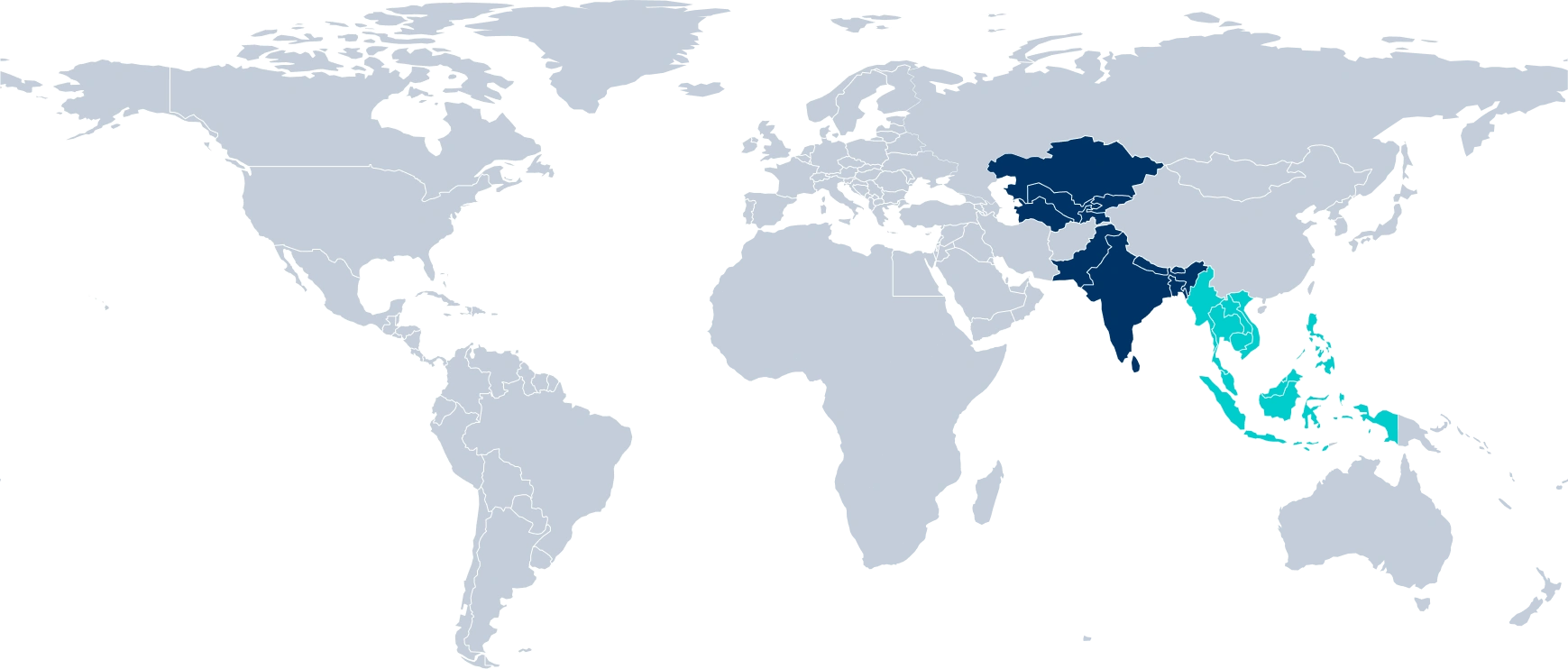

As a core equipment provider for the paper industry, we deliver complete production line systems for kraft linerboard, corrugated medium, tissue, and specialty papers. Leveraging proven expertise from China’s leading paper mills, we offer cost-effective, high-performance solutions tailored to emerging markets like Southeast Asia, the Middle East, Russia, and South America, while supporting compatibility upgrades for legacy European/Japanese equipment.

Core Equipment Matrix

End-to-End Integration for Diverse Paper Grades

Approach Flow System

- Low-pulse fan pump + Low-pulse screen

- Multi-stage cleaners (≥98% impurity removal)

- Pulse-attenuated headbox (CD basis weight deviation ≤0.8%)

Forming & Dewatering Units

Crescent former

Cost-efficient solution for tissue (12-40g/m²)

Triple-layer Fourdrinier former

Optimized for kraft linerboard (120-250g/m²) & corrugated medium (70-120g/m²)

Four-layer Fourdrinier former

Designed for high-grammage board (300-500g/m²) & industrial-grade specialty papers

Energy-Saving Sizing Systems

Film transfer size press

Closed-loop starch recovery (35% reduction in starch consumption)

Tray size press

Adjustable sizing volume (8-15g/m²)

Press Section

Low-grammage press(≤120g/m²)

Four-roll three-nip configuration (80→250kN/m linear pressure gradient)

Mid-high grammage press(120-250g/m²)

Φ1650mm blind-drilled press roll (post-press dryness 42%-46%)

High-speed press(≥800m/min)

Modular units with stepless dynamic pressure control

Pressure Dryer Section

Cast dryers

5kg/cm² standard pressure (400-800m/min mid-speed lines)

Yankee steel-can dryers

10kg/cm² high-pressure design (supports 1200m/min+ operation)

Smart Control Systems

- DCS distributed control (≤50ms data sampling)

- QCS closed-loop quality control (real-time moisture/basis weight adjustment)

- Multilingual HMI (CN/EN/RU/AR)

Zhengzhou Manufacturing Edge

Modular Design

Climate-Adaptive Engineering

Global Agility

Flexible Configuration

- Flexible Configuration: 2400-6600mm

- Speed zones: 300-1000m/min

Extreme Environment Adaptation

Arctic Edition

-45℃ hydraulic systems + anti-freeze lubrication (Russia/Central Asia)

Arctic Edition

-45℃ hydraulic systems + anti-freeze lubrication (Russia/Central Asia)

Cost Leadership

Key rollers 35% lower TCO vs. European equivalents, with spare parts hubs in Zhengzhou, Kazakhstan, and Vietnam

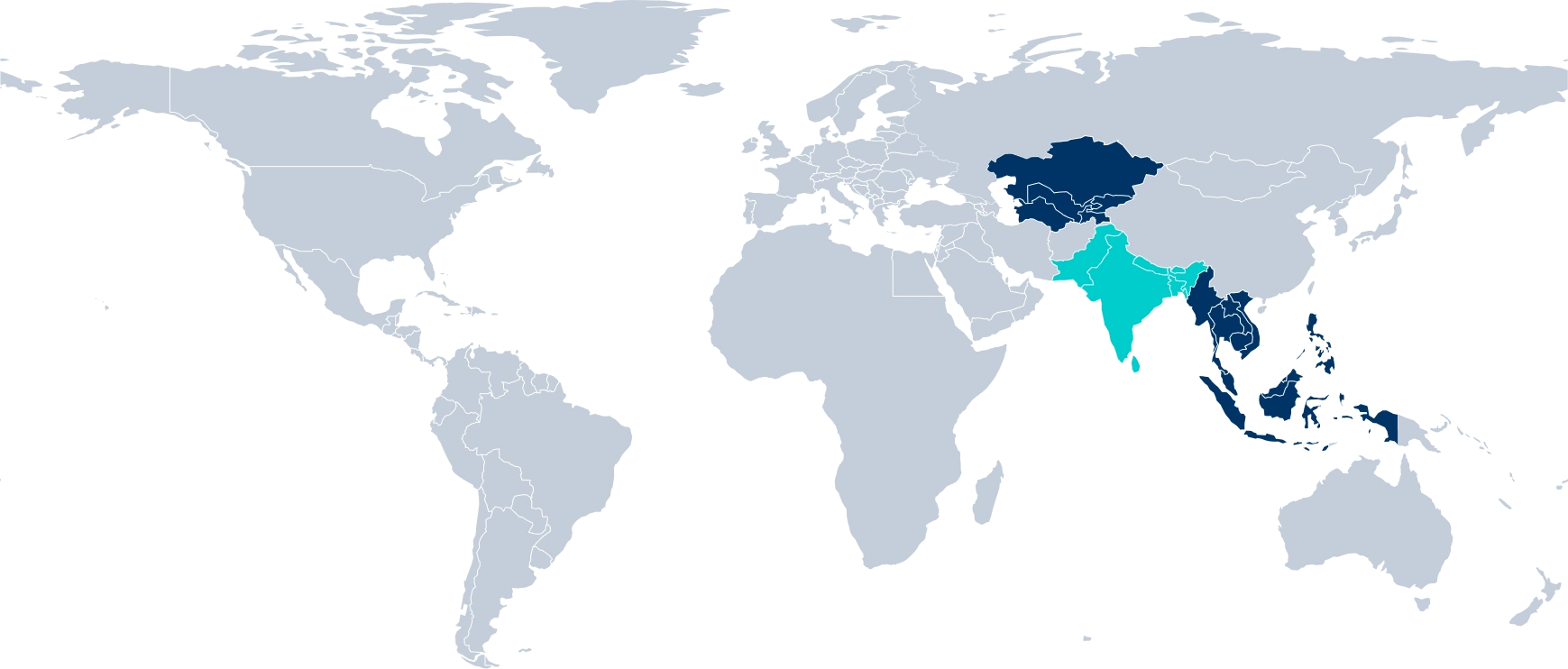

Global Project Highlights

Full Lifecycle Services

Seamless Support from Blueprint to Operation

Retrofit Planning

Compatibility analysis for Voith/Valmet legacy systems

Project Execution

Modular delivery (≤72hr downtime)

Ongoing Optimization

- Monthly efficiency reports (12 KPIs tracked)

- Predictive maintenance (roll lifespan monitoring)

- 24/7 multilingual support from Zhengzhou Tech Hub

OUR PRODUCTS

Provide high-quality products

-

PDF Title03

with energy consumption simulation

-

PDF Title02

with energy consumption simulation

-

PDF Title01

with energy consumption simulation