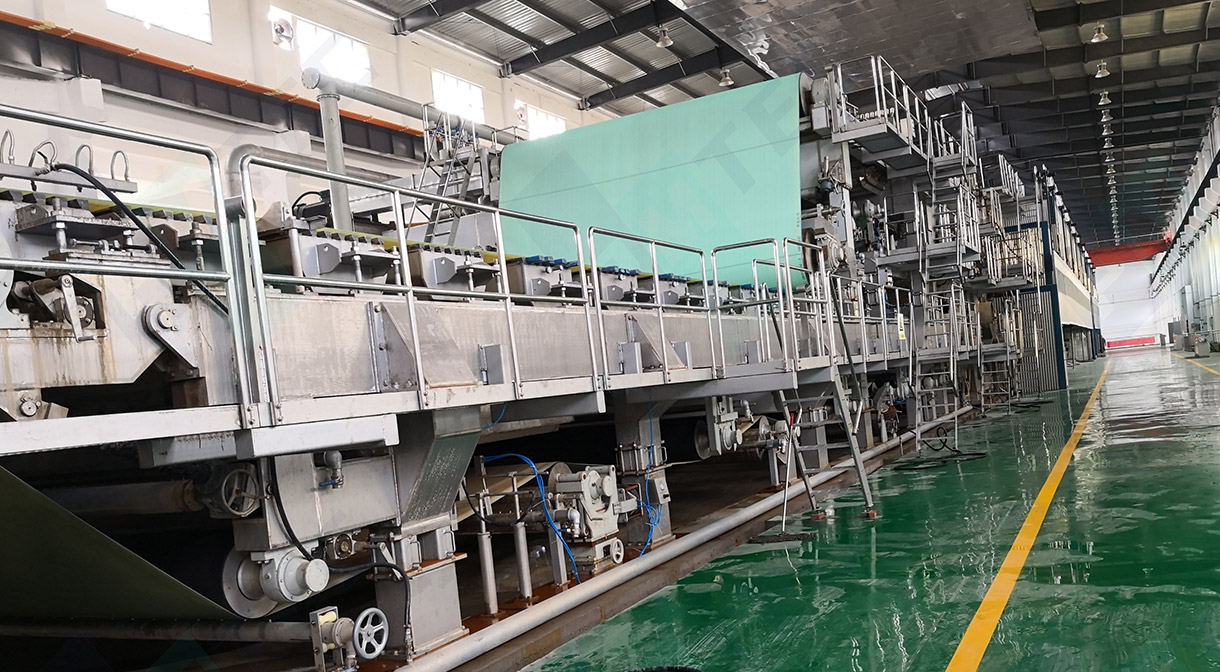

Core Equipment Configuration

Precision Engineering for Corrugated Paper Production

Forming Section

Single Fourdrinier Former

Economical solution for 80-120g/m² grades (300-600m/min)

Twin-Wire Former

Enhanced solution for 120-160g/m² high-strength grades (400-750m/min)

Press Section Optimization

Patented Four-Roll Three-Nip Configuration

Designed for low-grammage corrugated paper, linear pressure gradient 80→250kN/m

1650mm Blind-Drilled Press Roll

HB220-250 surface hardness, ≥5-year lifespan

Dynamic Linear Pressure Adjustment

grammage switching response <15 minutes

Drying System Enhancements

High-Efficiency Siphon Drainage Dryer Group

Ø1800mm, surface temperature deviation ≤±2℃

Front Vac Dryer Group

optimized for high-speed drying of ≤160g/m² grades

Hood System Options

open-type or fully enclosed heat-exchange hoods, selected by speed

Key Subsystems

Vacuum System

Turbo vacuum pump (25% lower energy consumption vs. conventional models)

Automation

QCS+DCS integration (moisture/basis weight control within ±0.5%)

Competitive Advantages

Modular Scalability + Cost Leadership

Flexible Configuration

- Machine Widths: 2800/3400/4800mm (expandable to 6600mm)

- Speed Tiers: Economy 400m/min, Standard 650m/min, Premium 750m/min

Material Compatibility

- 100% recycled fiber support 【OCC (ISRI #11 / #12)】

ROI Assurance

- 40% lower roll costs vs. European solutions

- 72-hour rapid delivery of pre-assembled press sections

Full Lifecycle Support

Seamless Transition from Installation to Production

- Project Execution

• CE-certified manufacturing + local compliance

• On-site commissioning by Chinese engineers (≤45-day debugging)

- Maintenance

• Critical component lifespan alerts (press rolls/vacuum pumps)