Core Equipment Configuration

Patented Cylinder Technology for Stratified Fiber Control

Multi-Cylinder Forming System

5-7 Cylinder Layering

• Independent basis weight adjustment per layer (interlayer bonding ≥250J/m²)

• Reject pulp utilization up to 35% (including containerboard system residues)

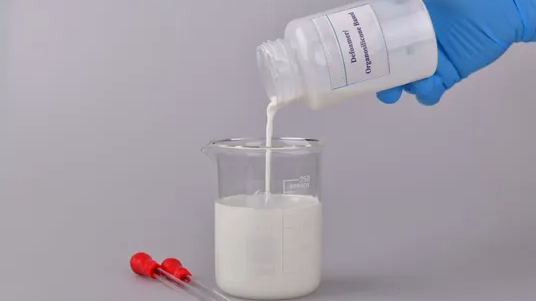

Sludge Integration Module

• Sludge dryness enhanced to 28% (patented dewatering)

• Oriented sludge fiber distribution (tensile strength loss ≤8%)

Advanced Press Section

Large-Diameter Compound Press

• Ø1800mm vacuum press roll (60-150kN/m linear pressure stepless adjustment)

• Interlayer moisture gradient control (MD variation ≤±0.25%)

Surface Sizing Enhancement

• Dual-layer curtain coating (starch/PVA dual-system)

• Closed-loop coat weight control (±0.5g/m² accuracy)

High-Efficiency Drying Section

Multi-Zone Dryer Configuration

• Front dryer group 110-130℃ rapid setting (interlayer bonding reinforcement)

• Back dryer differential speed drive (paper shrinkage ≤0.015%)

Heat Recovery

• Condensate heat reuse (steam consumption ≤1.6t/ton paper)

• Dryer surface temperature deviation ≤±1.8℃ (IR monitoring)

Competitive Advantages

Waste Valorization + Layer Precision + Patent Edge

PM’s Patents

- Cylinder interlayer coupling control (core patent)

- Sludge fiber orientation technology (Patent ZL2022XXXXXXX)

Performance Guarantee

- Ring crush index ≥20N·m/g (200g/m² basis)

- Interlayer bonding CV ≤2.8%

Cost Leadership

- Raw material cost reduced by 18% (reject pulp/sludge substitution)

- Press roll maintenance interval extended to 3 years

Full Lifecycle Support

Closed-Loop Service from Waste Analysis to Process Optimization

- Material Adaptation

• Reject pulp fiber morphology lab (interlayer bonding simulation)

• Sludge calorific value & ash content analysis

- Patent-Driven Delivery

• On-site commissioning by Liu Hongtao’s team (≤30-day ramp-up)

• Preloaded 20+ production profiles in cylinder control database

- Sustainable Upgrades

• Sludge drying system retrofit (moisture reduced from 80% to 28%)

• Press section white water recycle rate increased to 92%