Core Equipment Configuration

Dual Technology Paths for Full-Scenario Coverage

Top-Feed Rewinder

Speed Range

1000-1500m/min

Applications

Precision cutting for tissue papers (12-50g/m²)

Jumbo roll handling (≤Φ4500mm)

Key Technologies

Dual floating unwind stand (tension fluctuation ≤±0.8%)

Laser edge alignment (deviation accuracy ±0.3mm)

Pneumatic rider roll (contact pressure adjustable 5-50N/m²)

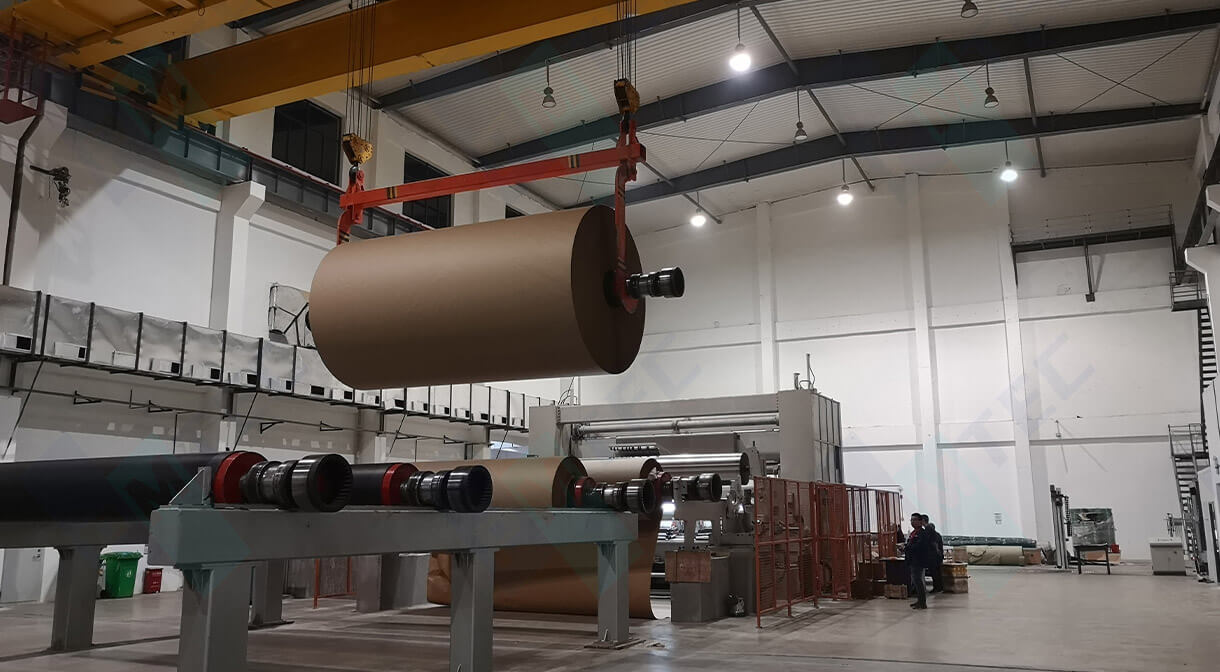

Bottom-Feed Rewinder

Speed Range

1200-2500m/min

Applications

High-speed rewinding for corrugated and linerboard (70-500g/m²)

Automated labeling for e-commerce paper rolls

Key Technologies

Dual drum drive (torque synchronization error ≤0.5%)

Dynamic load balancing (vibration ≤2.5mm/s)

Intelligent defect detection (hole/stain recognition accuracy ≥99%)

Intelligent Control System

Multi-motor synchronization (EtherCAT response ≤1ms)

Roll diameter prediction algorithm (diameter error ≤±1.5mm)

Automated labeling for e-commerce paper rolls

Energy monitoring module (power consumption ≤8kWh/ton paper)

Core Advantages

Dual Technology Paths for Full-Scenario Coverage

Flexible Adaptation

Width options

2800/3600/4800mm (expandable to 6600mm)

Interface compatibility

Seamless integration with upstream equipment

Performance Assurance

- Key rollers balanced to G2.5 (ISO 1940 standard)

- Gearbox lifespan ≥60,000 hours (AGMA 2001 certified)

Cost Efficiency

40% lower TCO compared to European counterparts (including logistics)