Core Technology Breakdown

Dual Technologies for Versatile Needs

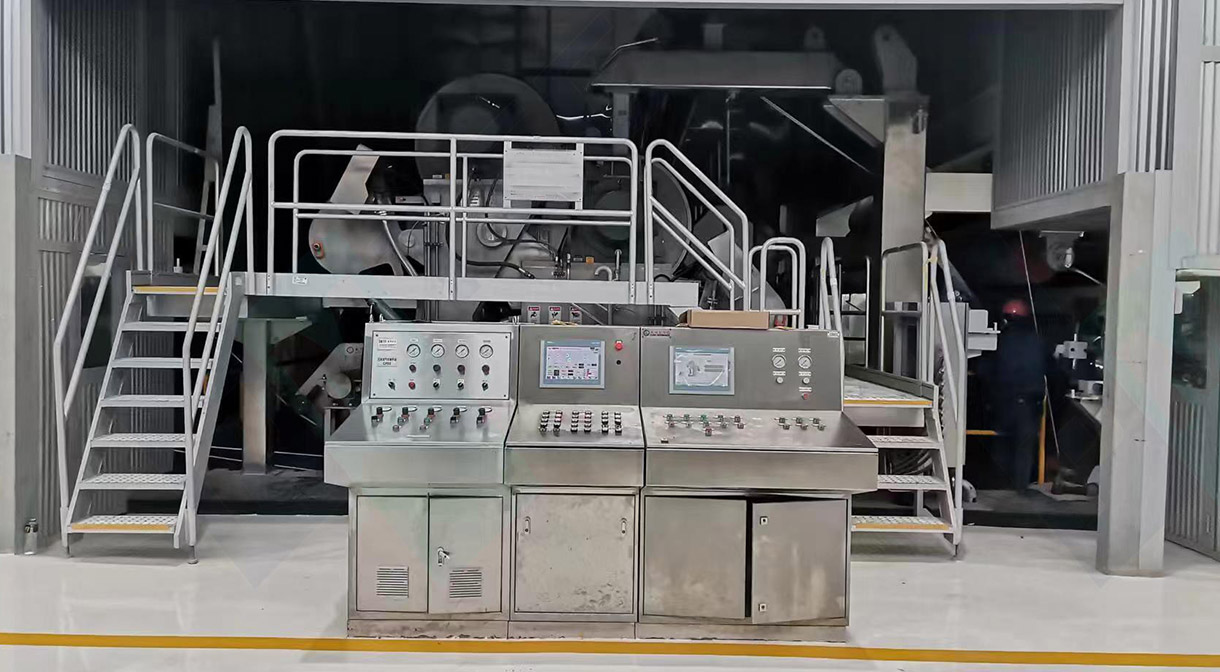

Gate Size Press

Working Principle

Dual-roll immersion coating forms a stable starch film through metering roll gaps, achieving double-sided sizing via submerged nip penetration.

Key Parameters

• Speed range: 80-400m/min

• Starch application: 1-8g/m² (single side)

• Starch solids: 8-14%

Applications

• Cultural paper surface strengthening (70-120g/m²)

• Corrugated medium water resistance (80-160g/m²)

Film Transfer Size Press

Working Principle

Metering rod precisely forms a starch film, transferred to the web via contact roll, with closed-loop residual starch recovery.

Key Parameters

• Speed range: 300-1200m/min

• Application accuracy: ±0.3g/m²

• Starch solids: 12-18%

Applications

• Liquid packaging board (200-400g/m²)

• High-strength kraft paper (100-180g/m²)

Core Technical Specifications

| Parameter | Gate Size Press | Film Transfer Press |

| Initial investment | $350k-$800k | $1.2M-$2.5M |

| Steam consumption/t paper | 0.25-0.4t | 0.12-0.2t (38-50% saving) |

| Starch adjustment response | 15-30min | ≤5min |

| Starch splash loss | 8-12% | ≤2% |

| Web moisture tolerance | 6-9% | 4-11% |

Customer Value Creation

End-to-End Optimization from Selection to Operation

Enhanced Flexibility

Gate Press : 4-hour starch→PVA switching

Film Transfer: No downtime grade changes

Quality Advancements

Film transfer coating uniformity CV

≤3.5% (vs.≥6.8% for gate press)

20-40% improved paper flatness

Cost Efficiency

Film transfer reduces starch usage 18-25%

Gate press maintenance cost <$15/operating hour