Stock Preparation

Core business areas

Laying the Foundation for High-Quality Paper Production

In modern papermaking, the efficiency and precision of the pulping system directly impact the quality of the final product. PM Company is dedicated to providing advanced pulping solutions tailored to meet diverse customer needs. Our pulping systems are designed not only to handle a variety of raw materials but also to ensure uniformity and stability of the stock, thereby enhancing paper quality and production efficiency.

Boiler Systems: Energy Solutions Engineered for Paper Production

EPC-Level Integration for Steam Cost Optimization

OCC Pulping

Efficient Utilization of Recycled Fibers

With the growing emphasis on environmental protection and the importance of resource recycling, OCC (Old Corrugated Containers) pulping has become an essential choice for many paper mills. PM’s OCC pulping system is specifically designed to process used corrugated boxes. Through a series of meticulous processes, including screening, cleaning, dispersion, and more, old cardboard is transformed into high-quality recycled fiber stock. This approach not only helps reduce reliance on virgin wood resources but also significantly lowers production costs.

In the following sections, we will delve into the working principles, technical features, and how our OCC pulping system can help you achieve greater economic and environmental benefits.

Market Wood Pulp Pulping

The Perfect Blend of Quality and Stability

For producers aiming for premium paper quality, using market wood pulp as the primary raw material is the preferred option. PM’s market wood pulp pulping system is designed to deliver stable and pure wood pulp stock, ensuring that every sheet meets the highest quality standards. From raw material reception and storage to stock preparation and delivery, each step is meticulously designed and strictly controlled to guarantee optimal production outcomes.

In the subsequent sections, we will explore in detail the specific processes and technical advantages of the market wood pulp pulping system, and how it can help your business stand out in today’s competitive market.

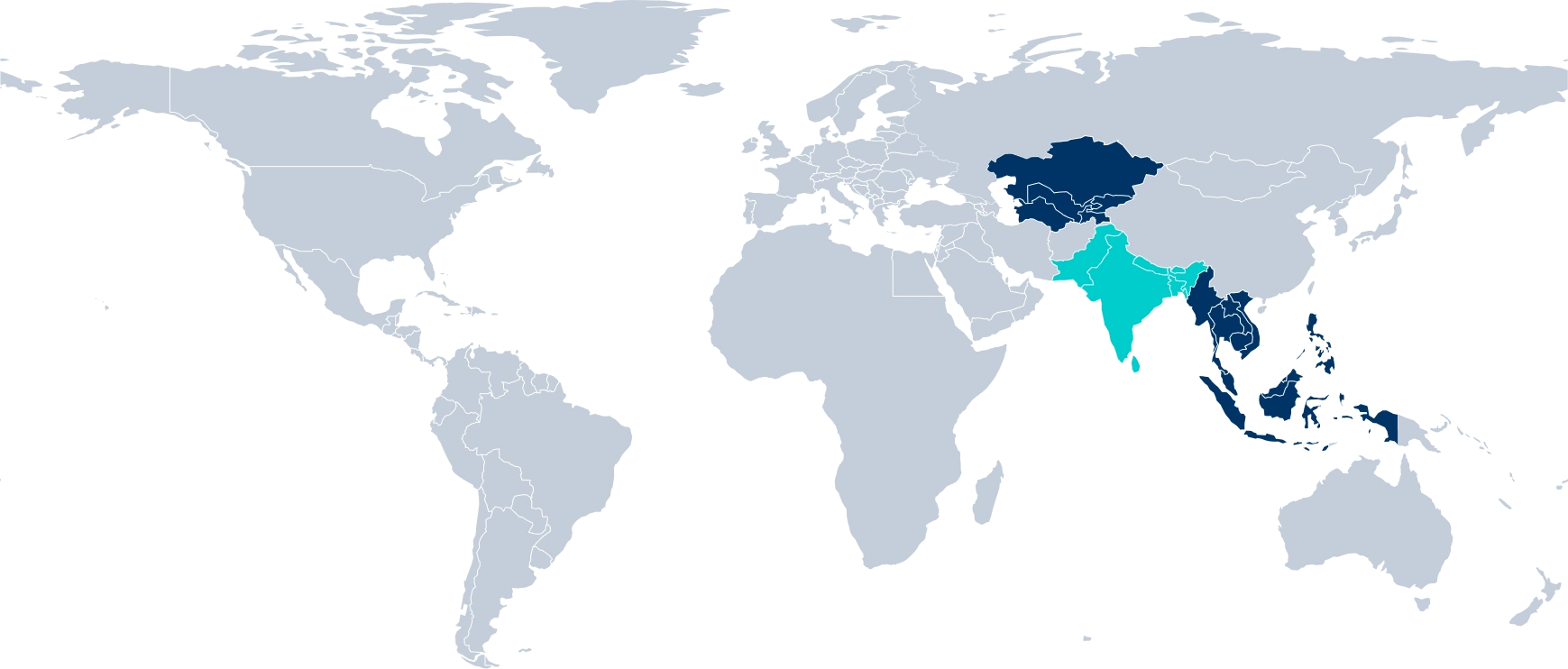

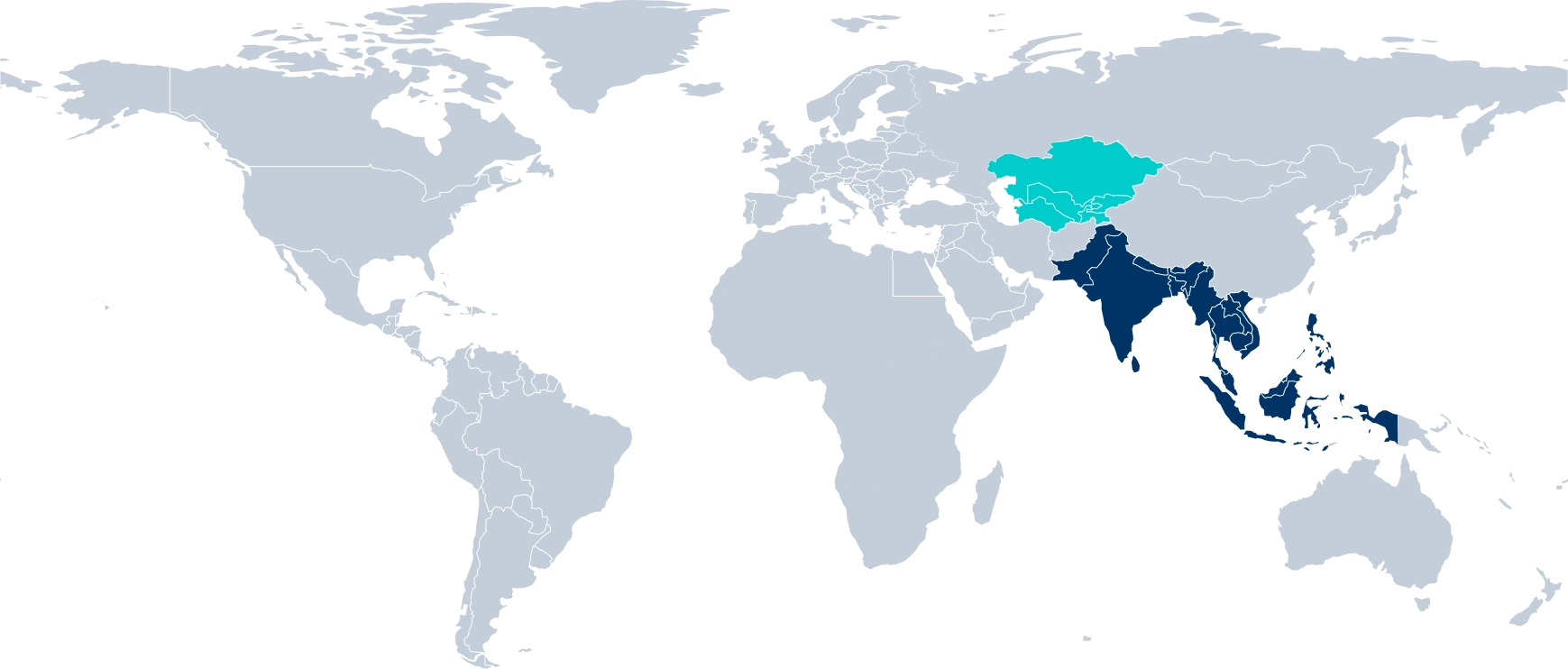

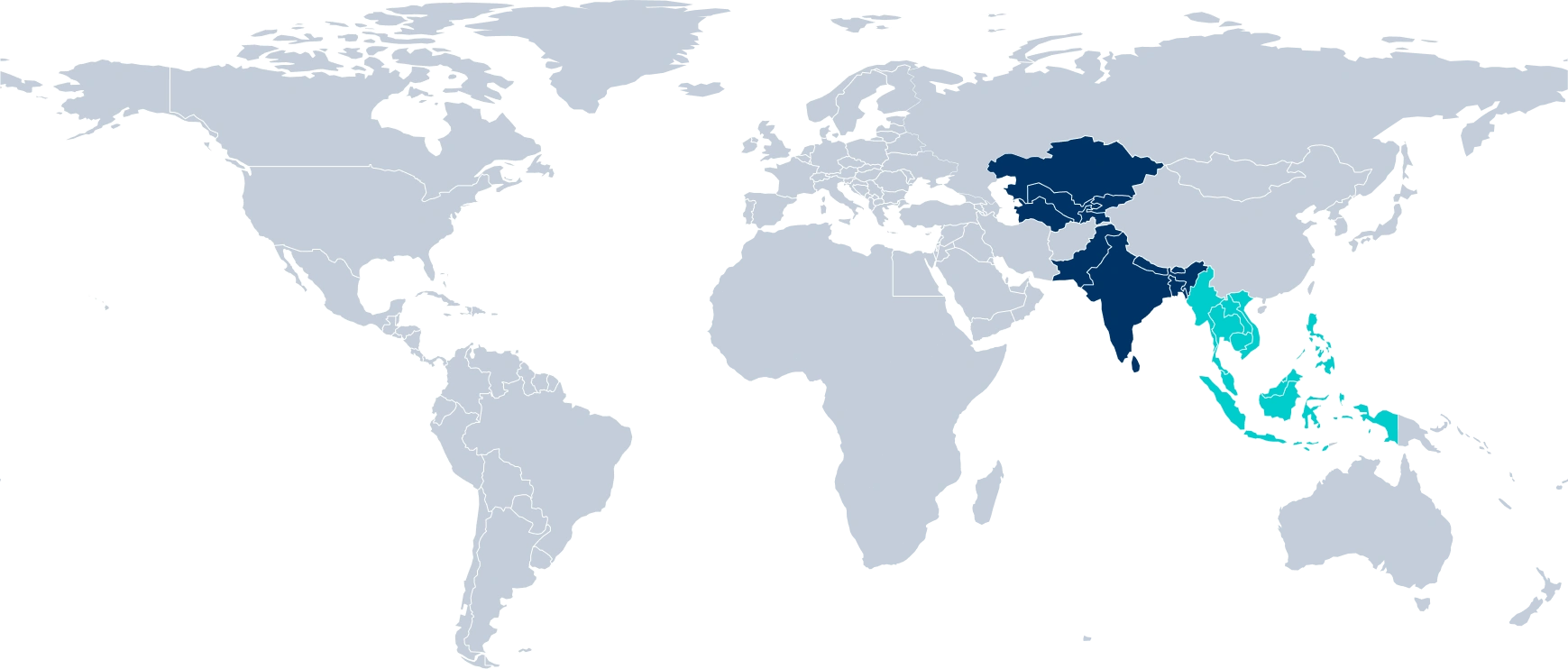

Global Project Highlights

OUR PRODUCTS

Provide high-quality products

-

High-Speed Rewinder Selection Guide

with energy consumption simulation

-

PDF Title01

with energy consumption simulation

-

PDF Title02

with energy consumption simulation