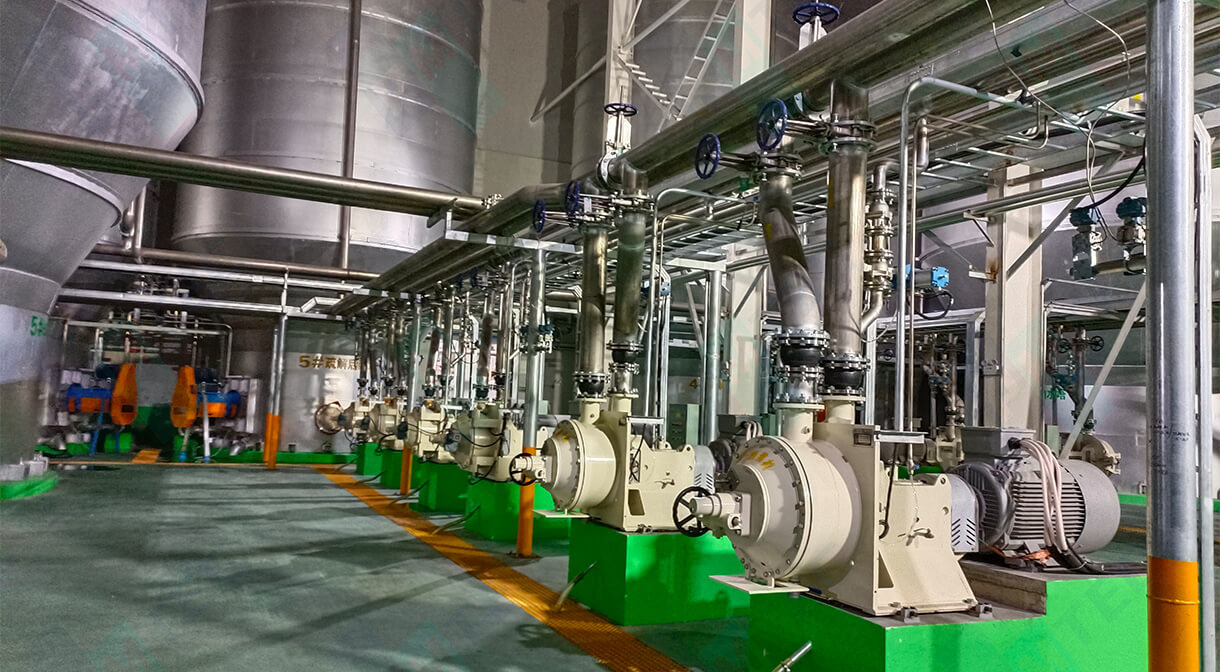

Core Process Flow

From Bales to Perfected Pulp: A Journey of Precision

1. “Automatic Dewiring” → 2. “Intelligent Medium-Consistency Pulping” → 3. ”Refiner Plate Protection & Purification“ → 4. ”Constant Specific Energy Refining“ → 5. ”Fiber Evening Optimization“ → 6. ”Precision Sheet Formation Control“

(Supports switchable continuous/batch pulping modes)

PM Tech’s Five Technological Breakthroughs

Technology Module | Innovative Design | Client Benefits

Intelligent Dewiring

- Fully automatic wire cutting + visual positioning

- 70% labor cost reduction, zero metal residue

S-MC Pulping Unit

- Patented S-shaped rotor + AI concentration control

- 30% pulping energy saving, ≥99.5% disintegration rate

Dual-Drive Refining

- Double-disc refiner with auto-gap calibration

- ≤2°SR freeness fluctuation, <3% fiber damage

Plate Protection System

- 3-stage magnetic filtration + dynamic buffering

- 40% longer plate life, 50% lower maintenance cost

Pulse Suppression

- Multi-stage damping + NLS inflow screen

- 15% improved sheet formation, 18% energy saving

Key Specifications & Certifications

Dual Technology Paths for Full-Scenario Coverage

Capacity: 30-300 T/D (multi-line parallel supported)

Compatible Pulps: NBKP, LBKP, bamboo pulp, and other market-grade chemical pulps

Certifications: CE, ISO 9001, TÜV Safety Certification

Why PM Tech ?

Technical Expertise

- Core team with 20+ years of R&D experience

Military-Grade Hardware

- Refiner plates: Tungsten carbide alloy (HRC≥62)

- Bearing lifespan: ≥32,000 hours (IP67 rated)

Global Support

- 48-hour technical response, 10-day emergency parts delivery (plates, screens included)

- Free refining efficiency diagnostic report