System-Level Value Beyond “Drainage”

The condensate removal system of a paper machine is far more than a simple “drainage” function. In the modern, high-speed paper machine dryer section, it is a critical efficiency unit that ensures high heat utilization and operational stability.

Its efficiency directly determines the upper limit of the dryer section’s energy consumption and the quality of the paper web.

PMTEC provides a complete interpretation of condensate removal, energy recovery, core components, and their connection to dryer section efficiency from a systemic perspective.

I. System’s Core Missions: Efficiency, Stability, and Recovery

The core value of the condensate system revolves around three main objectives:

1. Ensuring Superior Heat Transfer Efficiency

The Lifeline of the Dryer Cylinder: After steam releases its latent heat and condenses into water inside the cylinder, this condensate must be continuously removed.

Eliminating Thermal Resistance: If condensate accumulates into a “water ring,” it forms a major thermal resistance, severely reducing heat transfer to the shell and the paper sheet. This is the primary cause of excessive steam consumption.

Objective: To keep the condensate layer on the inner shell surface as thin as possible for the most efficient heat transfer.

2. Maintaining Dryer Section Operational Stability

Temperature Control Foundation: Unstable condensate removal leads to significant temperature fluctuations in the dryer cylinder.

Quality Assurance: Temperature instability directly causes quality issues such as moisture variation and wrinkles on the paper sheet.

Steam-Water Interface: The system helps establish a clear “steam–water interface” inside the cylinder, ensuring stable steam space operation.

3. Achieving Maximum Energy Recovery

The “Cost Excavator”: High-temperature condensate (usually near saturation temperature) contains significant recoverable thermal energy.

Recycling and Reuse: Flashing technology recovers low-pressure steam for reuse in low-pressure dryer groups or hood heating ; the remaining hot water is used for process preheating or boiler feed water. This can substantially reduce fresh steam consumption and operating costs.

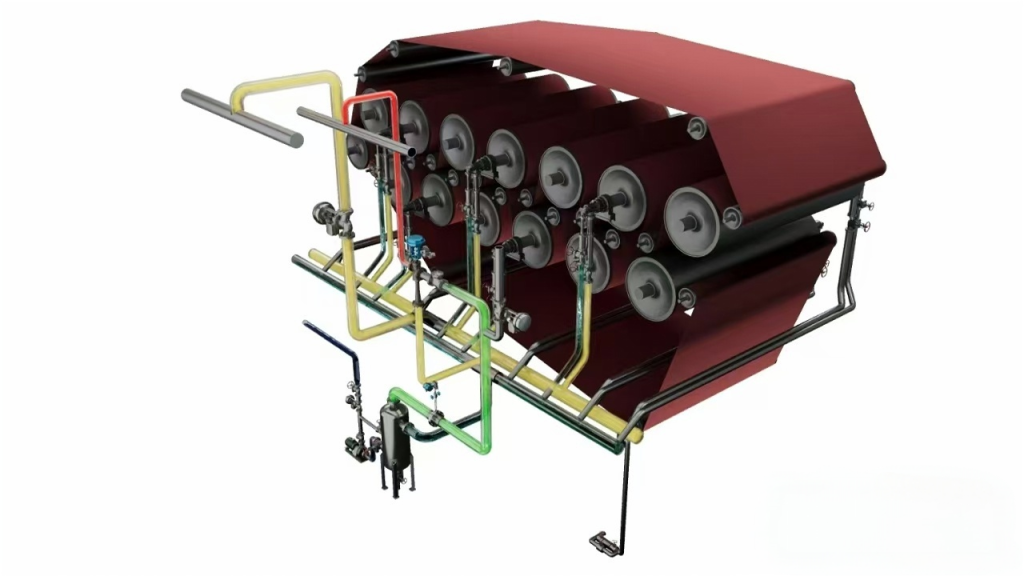

II. System Workflow and Core Component Analysis

The condensate system is a closed-loop, precise energy cycle.

2.1 Complete Workflow Overview

1、Steam Entry: Steam enters the dryer cylinder, releases latent heat, and forms a condensate film on the inner shell (main thermal resistance).

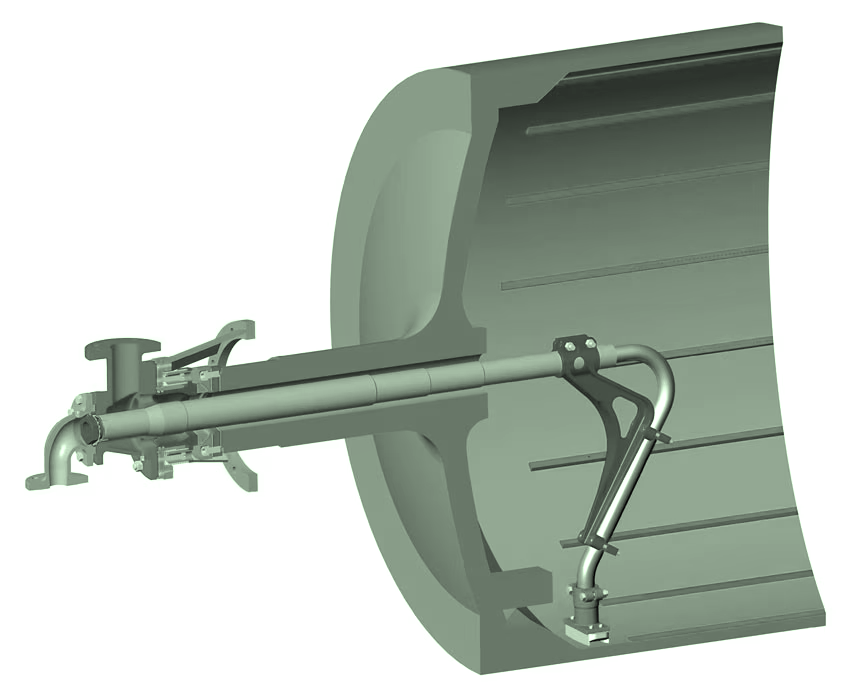

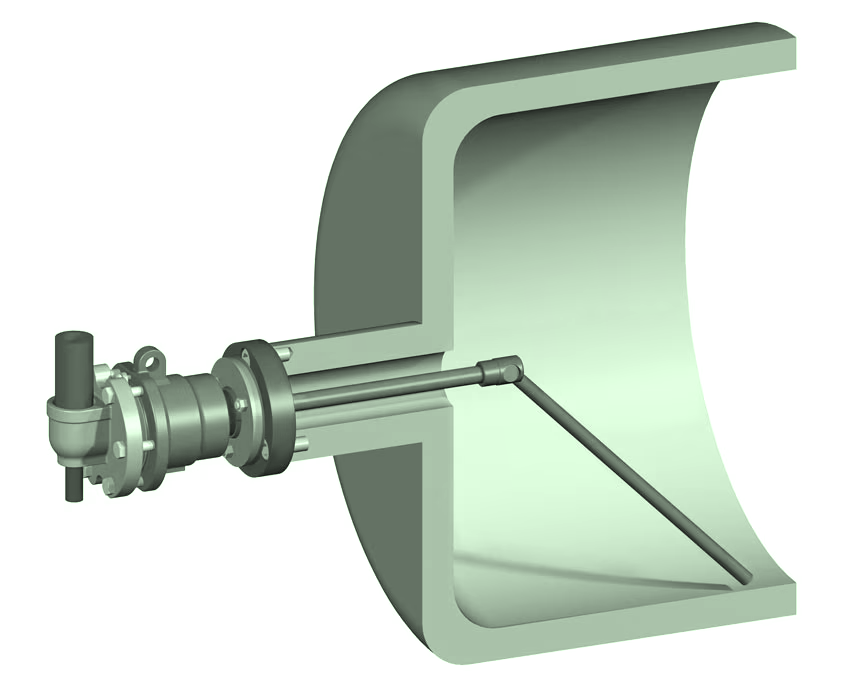

2、Syphon Removal:The condensate is continuously and timely captured and removed by the syphon system.

3、Flashing Separation:The mixed steam–condensate flow enters the Flash Tank. Due to the sudden pressure drop, part of the condensate flashes into low-pressure steam.

4、Energy Reuse:The low-pressure flash steam is routed to low-pressure dryer groups or the hood system.

5、Material Collection:The remaining high-temperature condensate is collected in the Condensate Receiver.

6、Pumping and Return:The hot water is pumped back to the boiler house or used for process heating, enabling further thermal utilization.

2.2 Key Components and Their Functions

| Core Component | Function Description | Key Metrics /Features |

| Dryer Cylinder | Heat exchanger body | Efficiency depends on condensate film thickness |

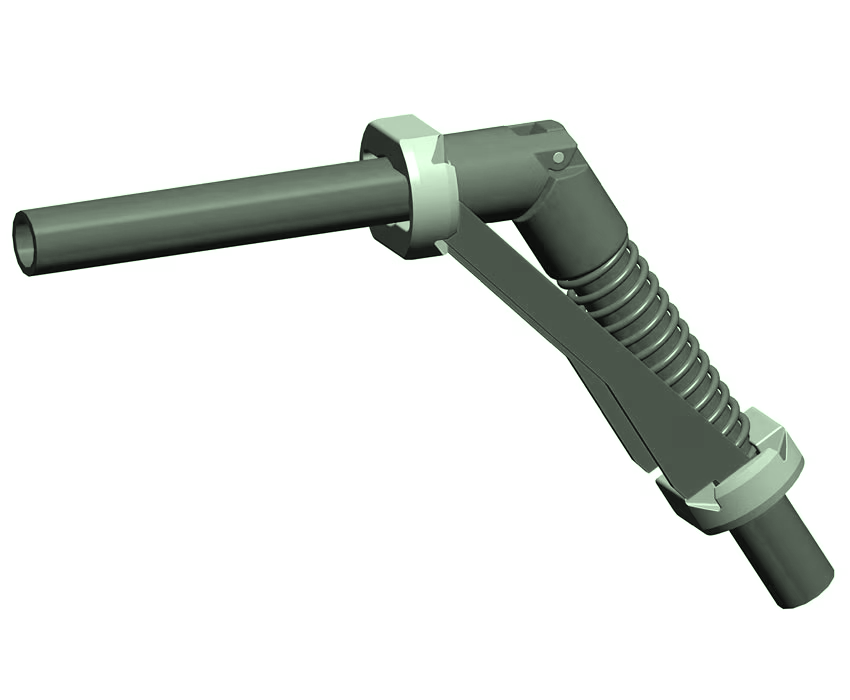

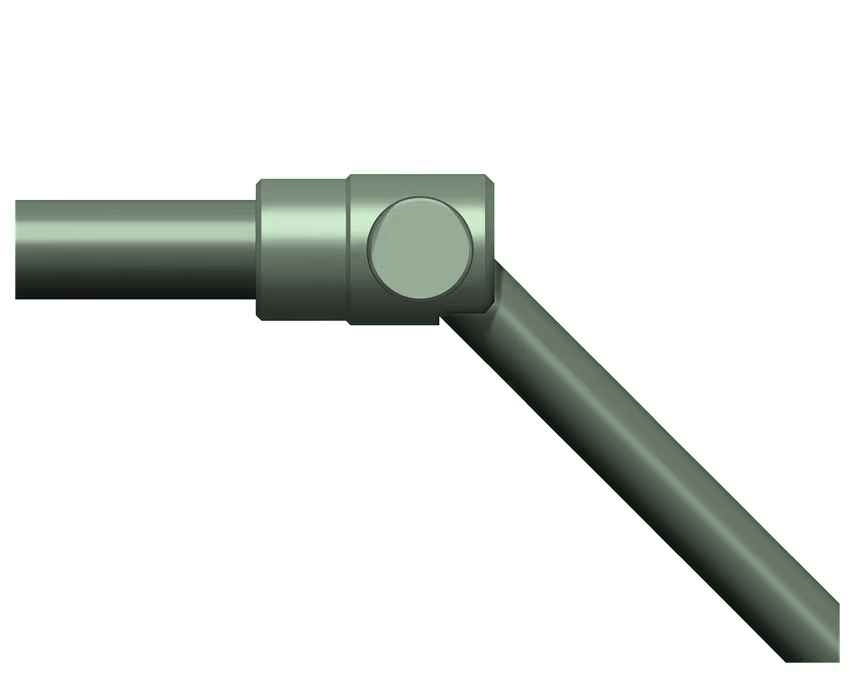

| Syphon | Key technology for continuous, efficient condensate removal | Fixed/Rotary types; Syphon clearance typically 1.5mm-3mm; Uses differential pressure/centrifugal force |

| Flash Tank | Energy “Sorting Station” for cascading utilization | Flash steam is reused in low-pressure dryers or hood heating |

| Condensate Receiver | Material “Collection Station” and pumping stabilization | Collects all condensate; Stable liquid level control to prevent pump cavitation; Returns to boiler |

III. Key Control Points and Common Issues

Accurate diagnosis of the condensate system is a sign of mature energy management.

| Issue | Typical Symptoms | Typical Causes |

| Reduced Syphon Efficiency | Noticeably low shell temperature; Increased steam usage; Uneven sheet drying | Syphon wear/misalignment; Tube blockage; Insufficient differential pressure |

| Water Hammer | Loud hammering noises in the piping; Potential damage to piping/supports | Accumulated condensate accelerated by steam forms a “water slug”; Steam trap failure or syphon malfunction |

| Low Flashing Efficiency | Elevated flash tank pressure ; Low secondary steam output | Insufficient condensate temperature ; Excessive backpressure in the venting system |

IV. Daily Inspection and Maintenance Essentials

4.1、The “Listen–Touch–Observe” Method

Listen

Listen for sloshing sounds inside the cylinders; Listen for hammering noises in the piping.

Touch

Touch the cylinder surface; abnormal cool areas across or along the shell usually indicate drainage issues. (With safety in mind)

Observe

Observe pressure/temperature trends on the DCS; Check flash tank pressure and steam trap performance.

4.2、Scheduled Maintenance Plan

Quarterly

Check and correct syphon clearance.

Semi-annually

Clean syphon tubes and filters.

Annually

Calibrate all instruments and comprehensively test steam trap performance.

V. Why Choose PMTEC for System Optimization?

PM specializes in paper machine thermal management engineering, offering end-to-end optimization solutions from the syphon to condensate recovery.

End-to-End Optimization Capability

Our services cover the entire condensate loop:

- Syphon design checking and upgrading.

- Steam-pressure optimization and distribution for dryer groups.

- Flash tank sizing and flashing performance improvement.

- Receiver stability and pump protection.

Data-Driven Energy Optimization

We utilize advanced data analysis to help mills achieve sustained cost reduction:

- Temperature/pressure trend analysis and fault prediction.

- Steam utilization rate and potential energy savings evaluation.

- System-level analysis based on heat balance and pressure distribution, not just component-level judgment.

Flexible Implementation and Global Support

Improvements can be implemented during short stops or without major shutdowns where feasible.

- PMTEC offers both global on-site guidance and remote technical support.

Conclusion: Mastering the Energy Efficiency Lifeline

The condensate system is the “unseen battlefield” of the dryer section. Mastering it means consistently controlling dryer efficiency, reducing steam costs, and achieving optimal energy recycling.

PM is dedicated to transforming your condensate system into a highly efficient, stable, and energy-saving “circulatory system” for the dryer section through precise system engineering.

Would you like us to conduct a systemic thermal balance and energy efficiency evaluation of your paper machine dryer section’s condensate system?