Why Choose Our Comprehensive Solutions for New Pulp and Paper Mill Projects?

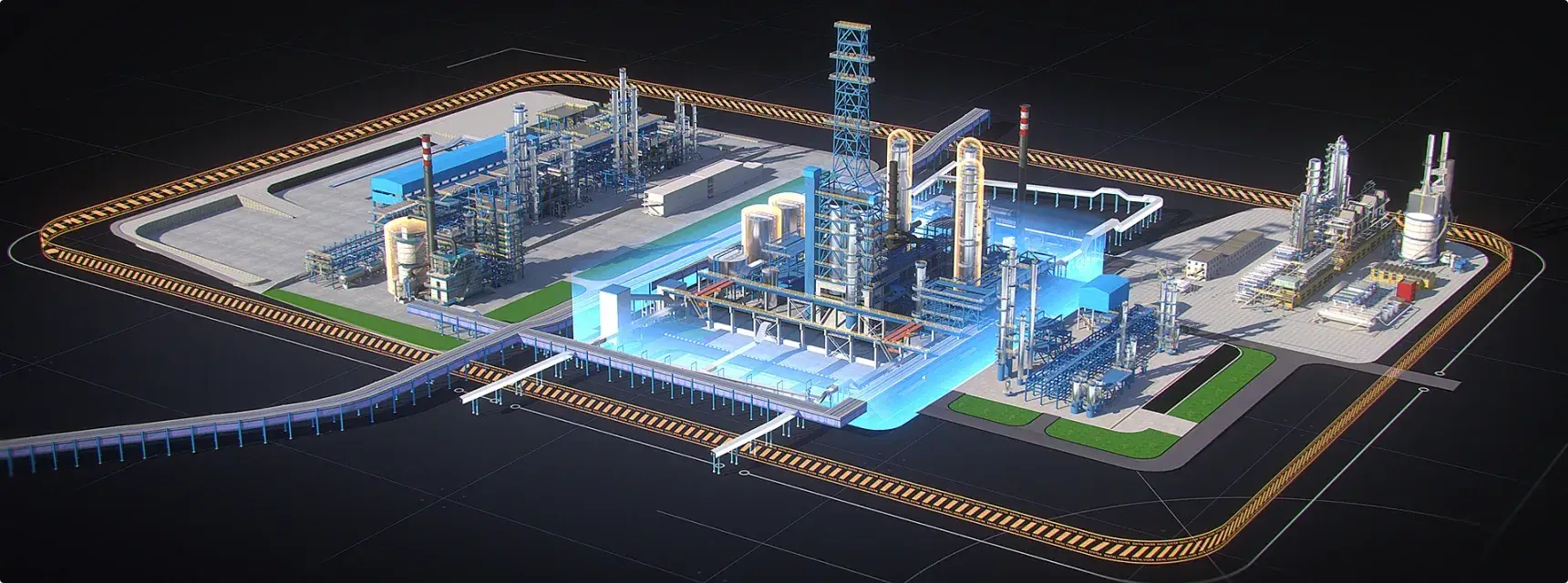

Full Process Coverage with Seamless Integration

From site selection assessment, feasibility analysis, equipment selection, process design, construction supervision, to production support, we cover the entire lifecycle of the project, ensuring scientific decision-making and close collaboration at every stage, avoiding information gaps and resource wastage typical of traditional segmented services.

Deep Industry Experience Tailored to Specific Needs

With over 20 years of experience in global pulp and paper projects, we are well-versed in the process requirements and market trends of various types of paper (packaging paper, Tissue, specialty paper), enabling us to tailor technical routes that optimize return on investment. For example:

Raw Material and Energy Cost Analysis

By matching local resources and designing circular economy solutions, operational costs can be reduced.

Environmental Compliance Planning

Anticipating international environmental regulations (such as EU BAT standards, China’s ultra-low emission requirements) to design wastewater treatment, exhaust gas purification, and solid waste recycling solutions.

Smart and Automated Upgrades

Integrating Industry 4.0 technologies to create modern, efficient, low-consumption pulp and paper production lines.

Specialized Design Optimization for Cost Reduction and Efficiency Improvement

Our technical team excels in process simulation and equipment layout optimization, minimizing redundant investments. Examples include:

- Shortening production line processes and enhancing space utilization

- Optimizing steam and power system configurations to reduce energy consumption by over 20%.

- Employing modular designs to flexibly accommodate future capacity expansion needs.

Strict Project Management Ensuring Timely Completion and Quality Assurance

Utilizing internationally recognized project management systems (such as PMI) and our proprietary digital monitoring platform, we achieve

Progress Transparency

Real time tracking of construction nodes, warning of delay risks;

Cost controllability

Strictly control budget overruns and avoid hidden expenses;

Quality standardization

Implement globally unified acceptance standards to ensure that equipment and engineering meet standards.

Continuous Operational Support Ensuring Long-Term Profitability

Post-production launch is not the end; we provide one or three years of operational management services, including

- Staff training and technology transfer.

- Production data monitoring and energy efficiency optimization

- Fault prediction and rapid response maintenance.

How Do Our Services Precisely Match Client Needs?

New Project Owners

Fully operational production line meeting capacity expectations

Traditional Paper Mills Seeking Upgrades

Achieve capacity enhancement and green transformation through process improvements and equipment updates.

Overseas Investors

Leverage our global service network to address localization compliance, supply chain establishment, and other challenges.

Case Study

Southeast Asia’s 300,000 Tons Per Year Packaging Paper Project

From Concept to Production: A Complete Guide to Turnkey Paper Machinery Projects

A client planned to establish a packaging paper plant in Southeast Asia but faced site selection disputes, unfamiliarity with environmental policies, and equipment selection difficulties.

We addressed these issues through

Preliminary Planning

Selecting the optimal site based on logistics, raw material supply, and policy incentives.

Design Optimization

Implementing recycled fiber pulping and biomass energy solutions to reduce carbon emissions by 30%.

Project Management

Coordinating suppliers from Europe and China to ensure on-time completion within 18 months.

Operational Support

Training local teams to achieve target output within three months.

More Cases

View More Cases

-

Turnkey Cultural Paper Project in Central Asia – T Paper, Uzbekistan

Turnkey Cultural Paper Project in Central Asia – T Paper, UzbekistanT Paper in Uzbekistan is a newly built large-scale modern papermaking enterprise dedicated to filling the local market gap for high-quality writing paper. The project planned to build a high-speed cultural paper production line with an annual output of 70,000 tons. The customer had limited experience in paper machine construction and placed extremely high demands on the project’s rapid delivery and long-term stable operation. At the same time, energy costs are relatively high in Central Asia, and energy conservation and consumption reduction are also key concerns for the customer.

-

Annual Output

|

70,000 tons

-

Location

|

Uzbekistan

-

-

Energy-saving and Speed-up Upgrade of Packaging Paper Machine in Southeast Asia – H Paper, Vietnam

Energy-saving and Speed-up Upgrade of Packaging Paper Machine in Southeast Asia – H Paper, VietnamH Paper in Vietnam is an important packaging paper production enterprise in Southeast Asia, mainly producing high-strength kraft paper and corrugated base paper. The original paper machine was introduced in 2006. After years of operation, problems such as equipment aging, declining efficiency, high paper break rate, and high energy consumption have become increasingly prominent, making it difficult to meet the rapidly growing market demand and increasingly stringent environmental protection requirements. Customers urgently need to upgrade the existing paper machine to increase capacity, reduce consumption, and reduce emissions.

-

Annual Output

|

70,000 tons

-

Location

|

Vietnam

-

-

Consistency and Flow Control Optimization – N Pulp Mill, Ethiopia

Consistency and Flow Control Optimization – N Pulp Mill, EthiopiaN Pulp Mill in Ethiopia is a large-scale bleached softwood pulp production enterprise. Fluctuations in pulp consistency led to unstable bleaching and inefficient chemical use. White water recovery rates were also suboptimal.

-

Annual Output

|

70,000 tons

-

Location

|

Ethiopia

-

Choose Us for Three Core Values

One-Stop Service

Eliminate the complexity of dealing with multiple suppliers by having a single team handle the entire process.

Technological Leadership

Combining Nordic environmental technology, Asian cost control expertise, and global supply chain resources.

Risk Control

Through rigorous feasibility analysis and project management, ensuring a project success rate exceeding 90%.