Why Do Clients Choose Our Project Management?

Proven Management System, Effectively Avoiding Common Risks

Adopting a flexible and adaptable management framework tailored to the specific challenges of the paper industry:

- Quality Risk: Strict quality inspection processes to ensure equipment interface compatibility and environmental compliance.

- Progress Risk: Detailed planning and regular monitoring to minimize delays in international equipment transportation;

- Cost Risk: Supply chain optimization and rational budget planning to avoid unnecessary expenses;

Global Resource Integration, Optimizing Cost Structure

- Supply Chain Optimization: Collaborating with multiple certified suppliers to reduce procurement costs for main equipment;

- Localized Execution: Establishing local support teams in different regions to shorten communication chains;

- Tax Planning: Leveraging local policy incentives to ease initial investment pressures.

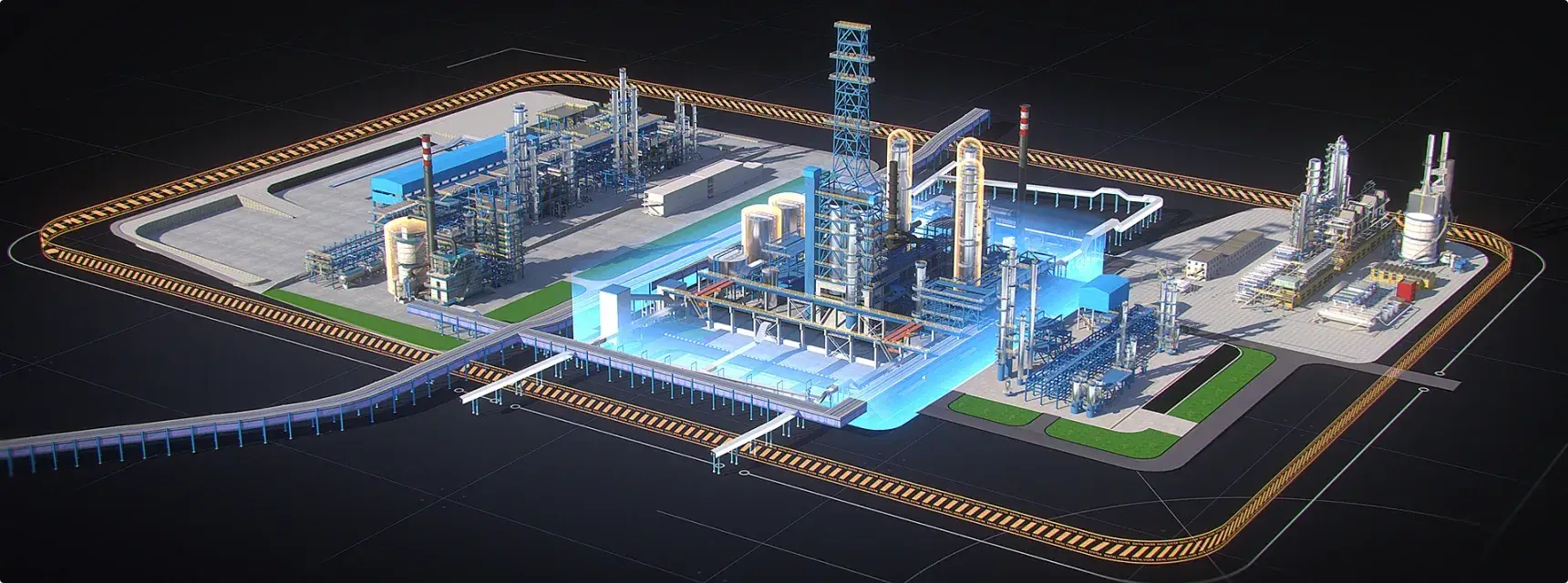

Digital Transparent Management, Enhancing Execution Efficiency

- BIM 4D Simulation: Visualizing construction processes to preempt potential conflicts;

- Cloud Supervision Platform: Real-time updates on progress, cost consumption, and quality issues;

- Risk Warning System: Predicting critical path risks based on data models and responding promptly.

Focus on Quality, Meeting High Standards

- Equipment Acceptance: Following strict precision standards for equipment inspection;

- Construction Standards: Adhering to internationally recognized construction norms;

- Environmental Compliance: Wastewater and exhaust gas treatment systems must pass third-party inspections.

Five Core Phases of Project Management

Project Initiation and Goal Alignment (1-2 Weeks)

Output the Project Charter: Clarify project scope, budget, and milestone nodes;

Form a cross-functional team: Including process engineers and other members.

Comprehensive Plan Development (3-4 Weeks)

Progress Plan: Break down work structures to weekly levels (WBS);

Cost Plan: Dynamic budget models covering equipment, labor, and taxes;

Contingency Plan: Set aside unforeseen fees and backup supplier lists.

Global Execution and Real-Time Monitoring (12-24 Months)

Progress Control: Use a “Red-Yellow-Green Light” warning mechanism to monitor key milestones;

Cost Control: Weekly analysis of cost deviations, triggering internal reviews if overspending exceeds 5%;

Quality Control: Third-party surprise inspections with image retention for traceability;

Guidance for Civil Construction: Providing technical guidance to ensure construction quality and progress.

Phase 4: Acceptance Transfer and Capacity Achievement (1-2 Months)

Mechanical Acceptance: Continuous 72-hour no-load/load testing;

Document Transfer: Archiving operation manuals, warranty agreements, and compliance certificates;

Capacity Ramp-Up: On-site support until reaching 90% of designed capacity.

Knowledge Accumulation and Continuous Improvement

Output the Project Review Report: Summarize lessons learned for future projects;

Client-specific database: Long-term traceable records of equipment maintenance and energy benchmarks.

Case Study

Southeast Asia’s 300,000 Tons Per Year Packaging Paper Project

From Concept to Production: A Complete Guide to Turnkey Paper Machinery Projects

A client planned to establish a packaging paper plant in Southeast Asia but faced site selection disputes, unfamiliarity with environmental policies, and equipment selection difficulties.

We addressed these issues through

Preliminary Planning

Selecting the optimal site based on logistics, raw material supply, and policy incentives.

Design Optimization

Implementing recycled fiber pulping and biomass energy solutions to reduce carbon emissions by 30%.

Project Management

Coordinating suppliers from Europe and China to ensure on-time completion within 18 months.

Operational Support

Training local teams to achieve target output within three months.

More Cases

View More Cases

-

Turnkey Cultural Paper Project in Central Asia – T Paper, Uzbekistan

Turnkey Cultural Paper Project in Central Asia – T Paper, UzbekistanT Paper in Uzbekistan is a newly built large-scale modern papermaking enterprise dedicated to filling the local market gap for high-quality writing paper. The project planned to build a high-speed cultural paper production line with an annual output of 70,000 tons. The customer had limited experience in paper machine construction and placed extremely high demands on the project’s rapid delivery and long-term stable operation. At the same time, energy costs are relatively high in Central Asia, and energy conservation and consumption reduction are also key concerns for the customer.

-

Annual Output

|

70,000 tons

-

Location

|

Uzbekistan

-

-

Energy-saving and Speed-up Upgrade of Packaging Paper Machine in Southeast Asia – H Paper, Vietnam

Energy-saving and Speed-up Upgrade of Packaging Paper Machine in Southeast Asia – H Paper, VietnamH Paper in Vietnam is an important packaging paper production enterprise in Southeast Asia, mainly producing high-strength kraft paper and corrugated base paper. The original paper machine was introduced in 2006. After years of operation, problems such as equipment aging, declining efficiency, high paper break rate, and high energy consumption have become increasingly prominent, making it difficult to meet the rapidly growing market demand and increasingly stringent environmental protection requirements. Customers urgently need to upgrade the existing paper machine to increase capacity, reduce consumption, and reduce emissions.

-

Annual Output

|

70,000 tons

-

Location

|

Vietnam

-

-

Consistency and Flow Control Optimization – N Pulp Mill, Ethiopia

Consistency and Flow Control Optimization – N Pulp Mill, EthiopiaN Pulp Mill in Ethiopia is a large-scale bleached softwood pulp production enterprise. Fluctuations in pulp consistency led to unstable bleaching and inefficient chemical use. White water recovery rates were also suboptimal.

-

Annual Output

|

70,000 tons

-

Location

|

Ethiopia

-

Choose Us for Three Core Values

One-Stop Service

Eliminate the complexity of dealing with multiple suppliers by having a single team handle the entire process.

Technological Leadership

Combining Nordic environmental technology, Asian cost control expertise, and global supply chain resources.

Risk Control

Through rigorous feasibility analysis and project management, ensuring a project success rate exceeding 90%.