Why Do Global Clients Choose Our Design Services?

Over 100 Project Experiences, Precisely Matching Needs

- Comprehensive Paper Types: Customized process designs for packaging paper, tissue paper, specialty papers (e.g., medical-grade, food-grade), etc.;

- Flexible Scale Adaptation: From small-scale mills producing 50,000 tons annually to large bases producing 500,000 tons, optimizing investment versus efficiency ratios;

- Global Delivery: Familiarity with EU BAT, China’s ultra-low emission standards, ensuring local compliance.

Innovative Process Design, Quantifiable Cost Reduction and Efficiency Gains

- Process Optimization: Using dynamic simulation modeling to shorten production line lengths by 15%-30%, reducing equipment investment;

- Energy Management: Integrating heat pump recovery and steam cascade utilization to decrease comprehensive energy consumption per ton of paper by over 20%.

Sustainable Plant Planning, Seizing Green Market Opportunities

- Resource Recycling Design: Increasing wastewater reuse rates to over 85%, solid waste resource management plans reducing landfill costs by 40%;

- Eco-compliance Assurance: Preparing for potential future environmental policy upgrades over the next decade, avoiding the need for secondary modifications.

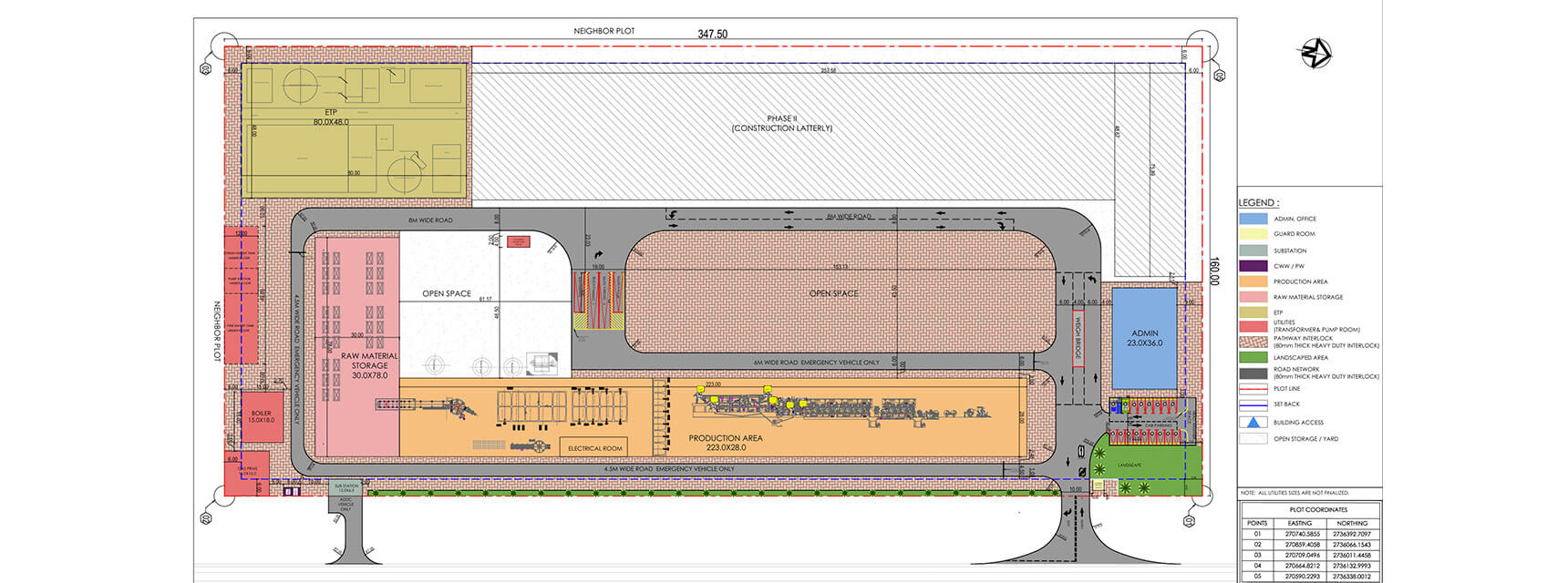

Scientific Factory Layouts, Enhancing Operational Efficiency

- Logistics Flow Optimization: Shortening paths from raw material intake to finished product output by 40%, improving forklift efficiency by 25%;

- Modular Expansion Design: Reserving interfaces for capacity upgrades, allowing future expansion without shutting down operations;

- Ergonomic Engineering: Optimizing workstations and inspection pathways according to ergonomics to reduce worker fatigue.

Six Core Design Steps Ensuring Accurate Implementation

In-depth Requirements Diagnosis (2-4 Weeks)

- On-site Inspection: Assessing nine dimensions including raw material characteristics, regional policies, and infrastructure;

- Pain Points List: Producing an Investment Return Model.

Conceptual Design: Balancing Innovation and Practicality (4-6 Weeks)

- Outputs: Process flow diagrams, equipment selection lists, energy consumption budgets;

- Highlights: Providing 2-3 comparative options, clearly defining CAPEX/OPEX differences.

D Simulation and Digital Twinning (3-5 Weeks)

- Utilizing AutoCAD, SolidWorks, and other tools to construct plant models;

- Simulating equipment operation, personnel movement, emergency evacuation scenarios to prevent design conflicts.

Multidisciplinary Expert Reviews (2 Weeks)

- Collaborating with mechanical, electrical, and environmental protection experts to ensure technical feasibility and compliance;

- Client participation in key milestone confirmations, ensuring 100% transparent communication.

Construction Drawing Delivery and Standardization (4-8 Weeks)

- Deliverables: Piping layout diagrams, electrical wiring diagrams, civil construction drawings, etc.;

- Additional: Equipment installation guidelines, acceptance checklists, reducing construction error rates.

Production Support and Continuous Optimization (1-3 Years)

- On-site Commissioning: Ensuring equipment operates as per design parameters;

- Data Tracking: Iteratively refining processes based on actual production data, achieving annual efficiency gains of 5%-10%.

Case Study

Design of a 150,000 Tons/Year Packaging Paper Mill in the Middle East

From Concept to Production: A Complete Guide to Turnkey Paper Machinery Projects

First venture into papermaking, lacking technical expertise;

Existing designs were fragmented, with incompatible equipment interfaces;

Required compliance with EU ESG certification for exporting to Europe.

Our Solutions

Process Re-engineering

Employing multi-disc filtration technology and online mesh cleaning systems to reduce water consumption per ton of paper from 10m³ to 5m³;

Smart Layout

Implementing U-shaped production lines to enhance logistics efficiency by 30%;

Regulatory Compliance

Successfully passing local environmental impact assessments in one go.

More Cases

View More Cases

-

Turnkey Cultural Paper Project in Central Asia – T Paper, Uzbekistan

Turnkey Cultural Paper Project in Central Asia – T Paper, UzbekistanT Paper in Uzbekistan is a newly built large-scale modern papermaking enterprise dedicated to filling the local market gap for high-quality writing paper. The project planned to build a high-speed cultural paper production line with an annual output of 70,000 tons. The customer had limited experience in paper machine construction and placed extremely high demands on the project’s rapid delivery and long-term stable operation. At the same time, energy costs are relatively high in Central Asia, and energy conservation and consumption reduction are also key concerns for the customer.

-

Annual Output

|

70,000 tons

-

Location

|

Uzbekistan

-

-

Energy-saving and Speed-up Upgrade of Packaging Paper Machine in Southeast Asia – H Paper, Vietnam

Energy-saving and Speed-up Upgrade of Packaging Paper Machine in Southeast Asia – H Paper, VietnamH Paper in Vietnam is an important packaging paper production enterprise in Southeast Asia, mainly producing high-strength kraft paper and corrugated base paper. The original paper machine was introduced in 2006. After years of operation, problems such as equipment aging, declining efficiency, high paper break rate, and high energy consumption have become increasingly prominent, making it difficult to meet the rapidly growing market demand and increasingly stringent environmental protection requirements. Customers urgently need to upgrade the existing paper machine to increase capacity, reduce consumption, and reduce emissions.

-

Annual Output

|

70,000 tons

-

Location

|

Vietnam

-

-

Consistency and Flow Control Optimization – N Pulp Mill, Ethiopia

Consistency and Flow Control Optimization – N Pulp Mill, EthiopiaN Pulp Mill in Ethiopia is a large-scale bleached softwood pulp production enterprise. Fluctuations in pulp consistency led to unstable bleaching and inefficient chemical use. White water recovery rates were also suboptimal.

-

Annual Output

|

70,000 tons

-

Location

|

Ethiopia

-

Choose Us for Three Core Values

One-Stop Service

Eliminate the complexity of dealing with multiple suppliers by having a single team handle the entire process.

Technological Leadership

Combining Nordic environmental technology, Asian cost control expertise, and global supply chain resources.

Risk Control

Through rigorous feasibility analysis and project management, ensuring a project success rate exceeding 90%.